Helllo all Im trying to find out the best and safest way to use the centers on my surface grinder. First, where in relation to the wheel to you want to have the centers, forward or closer to the center of the wheel? Also when taking cuts, how much would you do to be safe? Iv gone as far as .001 and it makes me a little nervous, but then again Im cutting stainless 40rc. Perhaps I the wheel might be too soft as its a J hardness. thoughts?

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

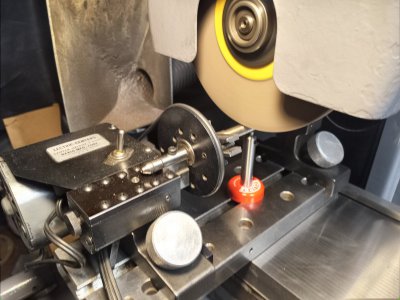

Harig lectric center usage

- Thread starter BCwoods

- Start date

- Joined

- Feb 5, 2018

- Messages

- 638

Search for Ox tool on u tube. Tom has a video showing how he sets up his centers for grinding.

Joe

Joe

- Joined

- Jun 7, 2013

- Messages

- 10,105

I'd think that you would want the center of the wheel as close to the center of the fixture as possible, as with any other cylindrical grinding setup, the further off center, there would be a measuring error due to the angularity, I'd think J hardness would be a good starting point, as to depth of cut, I would think that in a light duty setup such as is used, it might be a bit much and cause accelerated wheel wear. That is quite an expensive piece of kit, one could find a good used cylindrical grinder for that money ($4195).

Im worried more about the wheel possibly catching the fixture and crashing. While I dont think this is a possibility I have so little experience with it. The guy on the youtube black rock machine shop mentions this. So yes letric centers are extremely expensive new. You can find these on ebay here and there, as I did. Expect to pay around 1,200-1500. However these to can need some TLC and like machines "Fixing" them with new parts available can be pricey. However they are kinda neat and somewhat anticalmatic once you get one. Iv been the to Harig factory and they recommend slick 50 to lube it as it does not leave residue.

I'm still having issues with some kind of weird harmonic that sets up when making light passes where the wheel will get progressive aggressive in its cut. Even with a steady rest this does not change. Maybe it's the wheel that's too hard and not really cutting? When it is in Contact there is little sparking

Attachments

Yea it sounds like the part heating up and bowing but that fixture has one end spring loaded, right? That should stop any axial compression in the part.

If the wheel is touching and not sparking, it sounds like it’s not properly dressed.

If the wheel is touching and not sparking, it sounds like it’s not properly dressed.

OK I figured it out more or less, I used a small center drill and now it seems solid and using coolant as always can help. This was not completely apparent before as the part felt tight but yea. Also I did replace the spring that pushes up into the center that slides back in forth.