I’m confused (1/8, 3/8, 5/8? 18, 19, 20, 27, or 28 TPI?) and should bow out, but here’s what I’m taking as givens:

- the photo appears to show a taper which indicates a pipe thread.

It does look that way, but threads look funny in photos sometimes. I'm pretty sure the quarter inch air fitting I found for comparison looks straight, but I can assure you it's not. I went with the OP's word that the threads are straight. He's the one that's had a caliper on them.

- but 1/8 BSPT is 28 TPI and 1/8 NPT is 27 TPI. Those threads in the photo don’t look that fine to me (could be wrong), and it seems odd a gauge marked 20 G would (nearly?) match 27 or 28 TPI.

I agree, that appears coarser than those.

So confused.

But I still think simply measuring the distance between 7 threads is the easiest way to determine the actual TPI for certain (hopefully 27 or 28TPI).

That would work, but I think collectively, now that the thread gauge in use has been sorted out, we've got collective wisdom now saying that "20G" is useful information, so I think that means it's been nailed down to a 3/8 BSF bolt thread.

I am not sure what the G stands for but I have a similar thread gage and the 20 is 20 tpi.

That's what we needed....

Never mind that the entire concept of a non-tapered pipe thread is new to me.

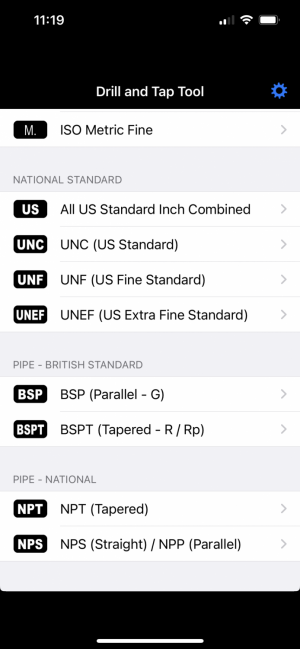

Straight pipe threads are out there... A lot of pipe railings are put together with straight threads. It's much easier to assemble that way when you're using multi-way fittings, nothing can come loose and "clocking" all the parts works out fine since they never really tighten.. (There's also a different tapered standard for that too if you need to be able to tighten a particular joint right down). A lot of disassemble lamps (table lamps for example, the kind made with tubes for the wires to run through) are made with parts that use straight pipe threads. So sloppy made usually due to the application, that they don't really warrant a sub category, but straight pipe nonetheless. At your breaker box, the metal fittings that clamp the wires where they to in- Those fittings and the locknuts that you hammer on with a screwdriver are straight pipe threads. They've got their own NP(x)(x) name but it escapes me right now. Maybe? MPSL for straight locking? Don't hold me to that. There's probably 30 US pipe standards, I only work with two.

All of the US pipe threads will all screw together to some degree. Might not be right, might not be to spec, may or may not do what you're hoping to do, but they'll all screw together. It's great when everything just works, but if you have a specific need to have something that's exactly right (or a drawer full of loose fittings...) It's kind of a nightmare. Probably why they're so misunderstood.