Hello to vintage mini-lathe experts! I was given a lathe as in the attached photos some years ago and would like to get it running to help my primary passion of vintage motorcycles restoration and racing, to make spacers and other parts, etc.

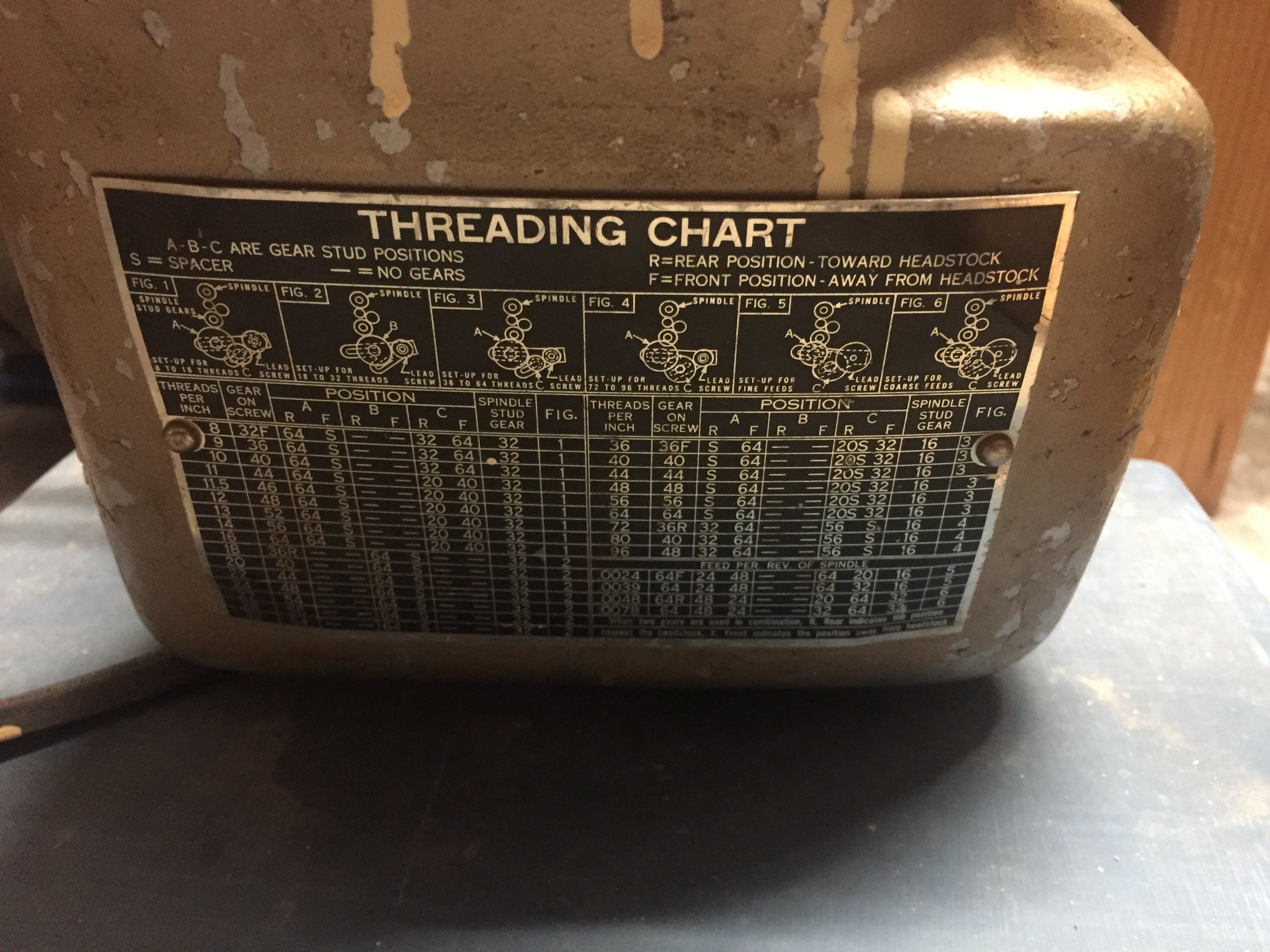

I'd like help to identify which model it is so I can search for documentation, parts, etc. as may be needed to get it operational. Based on looking at various internet photos, it looks like it may be a Sears 101 or 109 though some details, like 3 mounting holes versus others I saw with 4 and it does not seem to have any motor mounting points, etc. suggest it may be a similar though not identical model? Looks like there may have been a maker/model logo but it's almost totally worn off.

Can anyone recognize the manufacturer and model?

What would be the best way to power this, motor size, speed control and mounting?

What do you think it will take to get this operational?

Else, if it's not really worth the effort to get this going, anybody got good use for it that could help fund something newer that can cut metric threads?

Thank you for any guidance you can offer, Philip Stephens.

I'd like help to identify which model it is so I can search for documentation, parts, etc. as may be needed to get it operational. Based on looking at various internet photos, it looks like it may be a Sears 101 or 109 though some details, like 3 mounting holes versus others I saw with 4 and it does not seem to have any motor mounting points, etc. suggest it may be a similar though not identical model? Looks like there may have been a maker/model logo but it's almost totally worn off.

Can anyone recognize the manufacturer and model?

What would be the best way to power this, motor size, speed control and mounting?

What do you think it will take to get this operational?

Else, if it's not really worth the effort to get this going, anybody got good use for it that could help fund something newer that can cut metric threads?

Thank you for any guidance you can offer, Philip Stephens.