- Joined

- Feb 7, 2012

- Messages

- 541

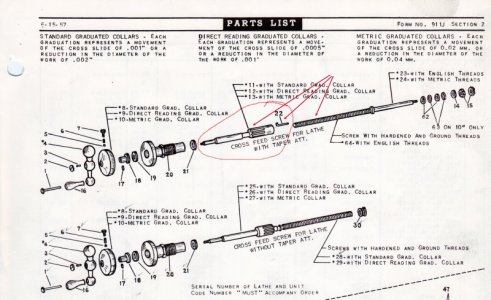

I added a taper attachment to my SB 10L about a week ago, and decided today to change out the cross feed screw. I've run into a bit of a dilemma, as naturally they don't just swap out. I'm not sure how to dis-assemble one and regroup it into the other, or if perhaps I can't even do that with what I have. Looking for help on (1) taking the original screw assembly apart, and (2) after that getting the longer one in the lathe and working. It seems like it has to come apart somehow, but I'm not seeing the right sequence.  Can anybody help or shed some light on what I need to do?

Can anybody help or shed some light on what I need to do?

Thanks in advance. I love a challenge, but I like to have some clue as to what I am supposed to do :biggrin:

Here's what I have here -

Thanks in advance. I love a challenge, but I like to have some clue as to what I am supposed to do :biggrin:

Here's what I have here -