If you guys want to precision-hone a lathe tool, get an Accu-finish from Glendo. You can put an extremely fine and accurate finish on HSS or carbide lathe tools and inserts with it, not to mention scraper blades. You cannot grind the radius that Stephan showed but for bringing it to a fine edge, yeah, the Accu-finish will do it. I happen to own one of these contraptions and I like it but I do not use it for honing most lathe tools; it is much faster to do it by hand and just as effective for most tools. I do use it to hone my HSS and carbide insert threading tools so I can control the geometry, though. I still need to make a fixture for sharpening gravers but that will go on the Accu-finish once I make it.

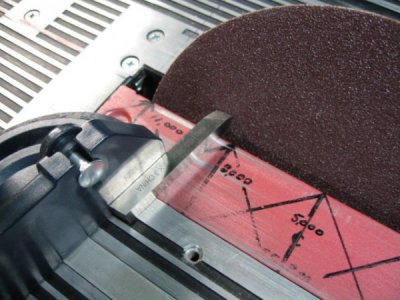

For grinding and shaping HSS lathe turning tools, a belt sander is far more effective than a bench grinder. It cuts faster, cooler, flatter and with better control, not to mention the ease with which you can change grits. No danger of a wheel exploding or having to be dressed, either. I used a bench grinder for a decade so I am very clear on which machine is better for this particular task, at least for me. You might want to consider it.