- Joined

- Dec 18, 2019

- Messages

- 6,448

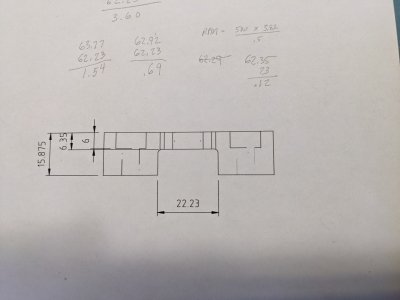

I have a 3" wide tool makers vise with 35mm high jaws. My 3" parallels are not tall enough to raise my part up high enough. I have a piece of 5/8" thick stock that I want to mill a 3/8" deep opening (9.525mm). So the thickness will be 0.250". Therefore the parallel needs to be such that the final surface is over the top of the vise. I do have some 6" parallels that are 1-1/4" high. This would give me 0.128" of the part in the vise (3.25mm). Since I am trying to hog out 3/8" of material, is that enough of the part in the vise? A very good size would be a parallel that's 30mm high, but from what I have seen such a beast is unobtanium.

The stock is 5/8"x1"x2.5" long. (The 1" depth is into the paper.) I need to mill out a channel that is 22.23mm x 25.4mm, so I intend to have at least 3/8" of material sticking out of the vise. Is there a simpler way to do this? I could just clamp it to the table, is that the best option?

The stock is 5/8"x1"x2.5" long. (The 1" depth is into the paper.) I need to mill out a channel that is 22.23mm x 25.4mm, so I intend to have at least 3/8" of material sticking out of the vise. Is there a simpler way to do this? I could just clamp it to the table, is that the best option?