- Joined

- Feb 24, 2019

- Messages

- 945

I finally broke down and bought a collet wrench. Before that I would use a pipe wrench on the collet collar and a crescent wrench on the top of the quill. It's not designed for a crescent wrench.

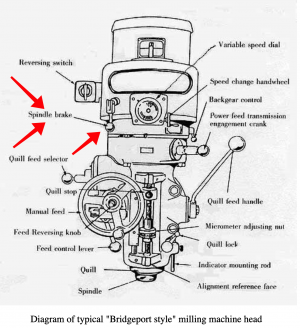

My mill head doesn't have a lock pin to hold the quill steady when changing collets or even when switching out the draw bar for that matter.

What would be a better way to hold the quill in place?

My mill head doesn't have a lock pin to hold the quill steady when changing collets or even when switching out the draw bar for that matter.

What would be a better way to hold the quill in place?