The application is a telescope tracking drive made from a worm gear. The main gear is aluminum, about 6.1 inches in diameter with 192 teeth. The worm is stainless about 3 1/2 inches long in total. The drive thread portion is 1 1/2 inches in the center. The threads are 1 inch in diameter and have a pitch of about 10 tpi. The worm shaft bearing surfaces are 1/2 inch diamter and about 1 inch long, on each end. The maximum revolutions are about 40 rpm.

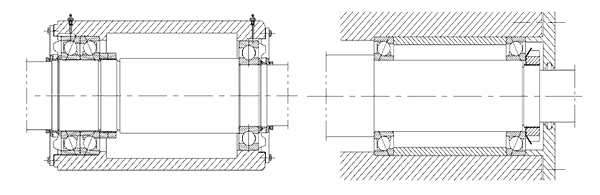

I have determined a critical factor in accuracy is the precision of maintaining the worm shaft rotation. My question is: What is the most bearing type for this application?

I had considered a pillow block bearing but realized the set screws would offset the bearing surface.

I have read about 'ceramic' bearings but have found specification.

Would bronze bearing offer sufficiently tighter tolerances?

Thank you in advance, Dan

I have determined a critical factor in accuracy is the precision of maintaining the worm shaft rotation. My question is: What is the most bearing type for this application?

I had considered a pillow block bearing but realized the set screws would offset the bearing surface.

I have read about 'ceramic' bearings but have found specification.

Would bronze bearing offer sufficiently tighter tolerances?

Thank you in advance, Dan