- Joined

- Dec 18, 2019

- Messages

- 6,458

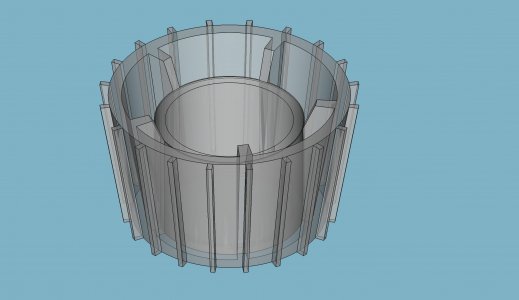

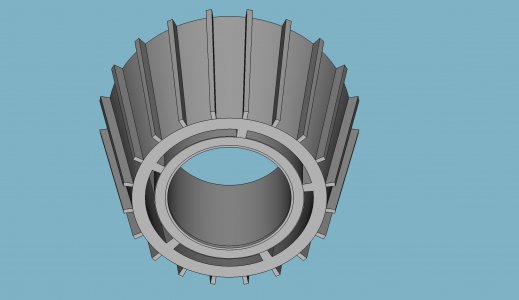

I realize I could make this out of PETG and it would probably work, but what's the fun in that? Trying to duplicate a filament spool holder for my PrintDry filament dryer. It seems the small size spool holder is too large to fit in a Prusament spool. so I designed a holder which is similar. There's not much on the base for a hold down, so I may use a brim. The original looks close to this and is made out of a rubber like material. So I am going to try TPU. This is a much smaller print than my previous one's and I hope not to stumble over the same issues.

The real one has twice as many ribs. I figure 20 of them are enough. If not, I'd change the polar pattern from 20 to 40.

There's a PETG bushing that fits in the hole and the shaft goes through that. I'll reuse the bushings for now.

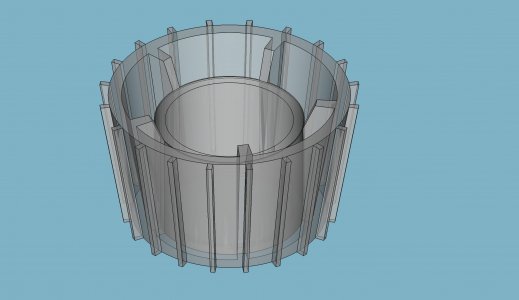

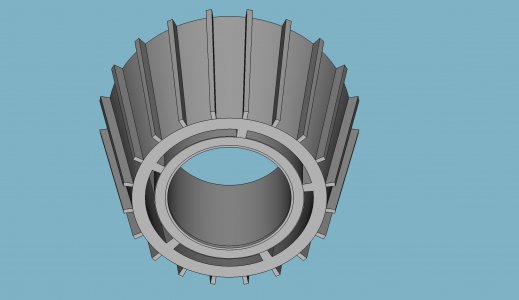

The real one has twice as many ribs. I figure 20 of them are enough. If not, I'd change the polar pattern from 20 to 40.

There's a PETG bushing that fits in the hole and the shaft goes through that. I'll reuse the bushings for now.