Very nice work! Have you built a liner lock from scratch?

That is on my list of projects!!

Why not make a framelock? A lot stronger and considered higher class.

im impressed, very cool. not to criticize, but with your skill level, why not just build the whole thing from scratch? again, not trying to "cut" (sorry) down your project, just curious. thanks.

Thank you guys. Maybe for a future project. Right now experimenting and learning from this low-cost knife is great since messing up is not so bad $$$-wise.

I just completed the second Thermite. Here are some photos from the build.

I started by sanding and scuffing the two parts to be epoxied:

Then used JB weld, and oiled the screws so that they would not get permanently attached:

To line up the two half's I used the long screws:

Once I had everything aligned, I clamped, removed as much excess as I could, clean holes/pockets, etc.:

This is why I used JB weld - I want to use these ceramic wheel bearings and a portion would need to be supported due to the hollow scale (for the spring assist):

So I measured the thickness of the original bronze washer against the ball bearing washer:

As expected, once I cut the pocket, the bearing one of the scales would rest on the G10, so I also purchased these to use behind the wheel bearings (I wish these were like 0.010" instead!):

Once I center the mill, I can then cut the pocket. Since these washers are more than 0.010", I can't quite cut as deep as I would like, so there will be a slight gap (more on that later):

Yes, the pocket is slightly larger than the new bearing, but that was the size of the closest end mill I had at hand:

Then do the other scale (solid steel), and assemble to check my handi work:

Here is the back, with the slight gap I mentioned (roughly 0.020"):

Note that even on the steel scale I need the thin hardened spacer since a portion of the bearing would be exposed otherwise:

As with the first Thermite, I have to drill the hardened steel blade to create a stop to hold the blade closed (since I removed the spring assist stuff):

Maybe not Space Shuttle accurate, but close enough:

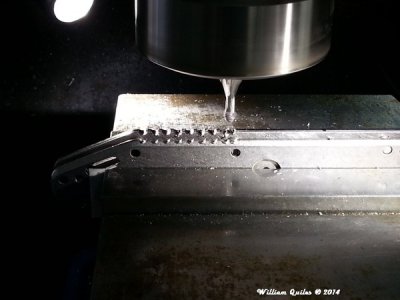

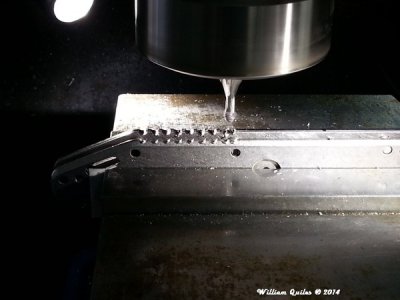

As before I cut the spine for better grip:

But I made the cuts near the end more shallow, since then activating the flipper edge, the original cuts were a little too deep and slow down the finger somewhat (the cuts were almost "too effective" !!!):

Did the back, but also a little bit on the other side for improved grip/ergonomics:

I "really" like this asymmetrical cuts in the top "much" better:

Now to work on the other area that needs (my opinion) work - the thickness and the "design" on the G10 scale:

And I applied a new pattern:

Much better feel/ergonomics and much better (my opinion) looks as well:

Close up of the two bearing "systems". The ball bearings are AWESOME in action. So much smoother and effortless, it is hard to describe:

After using it for just one day, I realized that the smooth scale is just too slippery, compared to the new one I made on the G10 side, so .....

Unlike the G10, which I made flat first (before cutting the new pattern), the steel scale is not "flat", but I did not want to remove any thickness and I wanted to preserved the stonewashed finish. So as a result, the new pattern is not quite perfect (second photo, lanyard side of the knife), but it turned out OK:

Like before, I enlarged the finger opening (better ergonomics for me):

And now I have my $25 dollar knife ready for more daily use. I have a few other, more expensive knives, with much better steel, etc., but this one now is "special" to me:

Will