- Joined

- Dec 18, 2019

- Messages

- 6,447

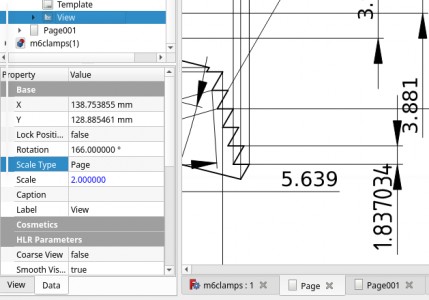

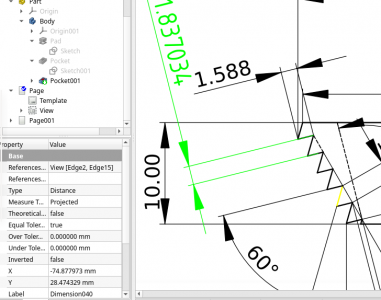

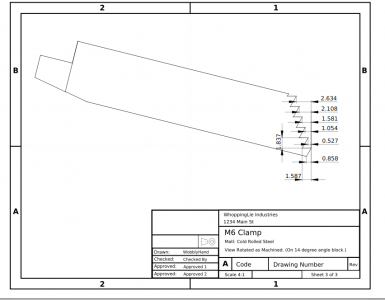

I've created a clamp that I'd like to machine. Having a bit of trouble dimensioning it in a way that I could machine the part. Basically, I'd like to create a cosmetic line that is exactly 104 degrees from the horizontal. There doesn't seem to be a way to easily do this in TechDraw. If I had such a line, I could dimension the distance from the vertices of the object to the cosmetic line. I can get an approximation to the angle, by hunting and pecking and placing a cosmetic vertex, and drawing a cosmetic line from the part to the cosmetic vertex. I need to get exactly 104 degrees, is there a way to do this? Or, is there a better way to accomplish something similar. Basically I want to mount the piece on a 14 degree angle and use a dovetail cutter. I need to know the offsets for the cuts.

Looking for some ideas. Thanks.

Looking for some ideas. Thanks.