- Joined

- Dec 18, 2019

- Messages

- 6,463

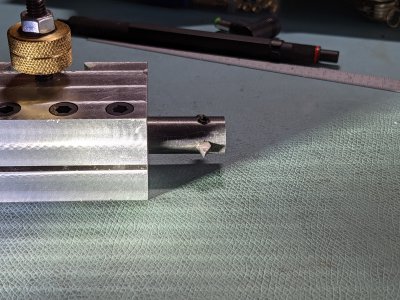

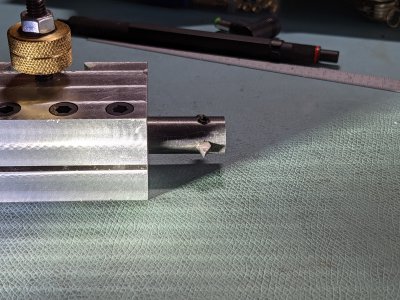

An update: The 3/8" LH threading bar I bought from Shars is ok for smaller stuff, but not so good for bigger stuff simply due to its diameter. Even choking up on the tool leaves quite a bit unsupported, almost 3/4". It chatters a bit. I used my 1/2" bar that I made and it is ok for easier to machine materials. It was chattering in thin walled 304.

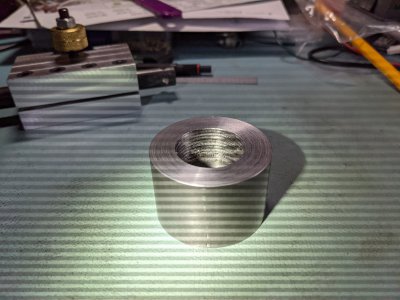

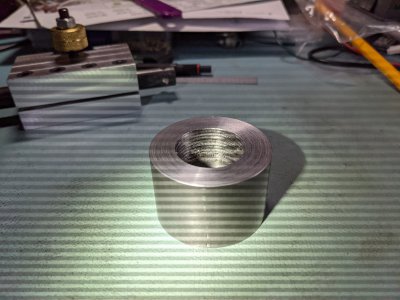

A few days ago, I tried the 1/2" bar on some 4140. The wall thickness was 10mm, still got a bit of rough cutting. Have a bit stick out which is as small as I can do, and the tool stick out from the boring bar holder is 3/4". The OXA boring bar holder is made of 7075. The quality of the cut isn't that good. There's some chatter marks on both sides of the thread. I also found the tip of the top seemed to have broken off. There is a small flat spot on the tip, which didn't used to be there. Unfortunately this is not obvious in the photo. Some of this is reflective of my tool grinding skills, which apparently needs improvement. Perhaps other parts are the rigidity of the platform, being a mini-lathe. Thought I would show the photos to see if anyone can think of some changes to make.

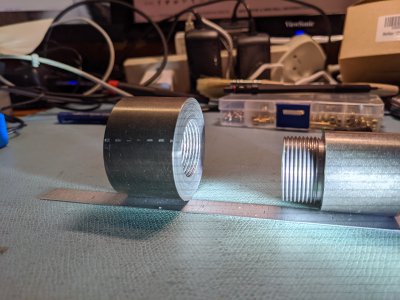

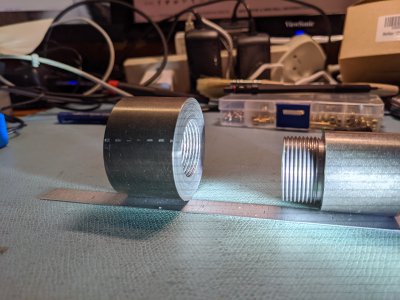

My LED flashlight is apparently strobing. I was trying to use it as fill light. Won't do that anymore. Male thread cut with SER1010 + AG60 insert in 1144.

A few days ago, I tried the 1/2" bar on some 4140. The wall thickness was 10mm, still got a bit of rough cutting. Have a bit stick out which is as small as I can do, and the tool stick out from the boring bar holder is 3/4". The OXA boring bar holder is made of 7075. The quality of the cut isn't that good. There's some chatter marks on both sides of the thread. I also found the tip of the top seemed to have broken off. There is a small flat spot on the tip, which didn't used to be there. Unfortunately this is not obvious in the photo. Some of this is reflective of my tool grinding skills, which apparently needs improvement. Perhaps other parts are the rigidity of the platform, being a mini-lathe. Thought I would show the photos to see if anyone can think of some changes to make.

My LED flashlight is apparently strobing. I was trying to use it as fill light. Won't do that anymore. Male thread cut with SER1010 + AG60 insert in 1144.