FWIW..... for those may be obsessing abt cutting gears "by the book",.......particularly with adjustable meshing , things are not so critical ......i have been using a 24 tooth stud gear on my 1895 Reed 14 in lathe that i cut w/ a # 6 cutter which was what i had on hand .....no problem in 12 years now.........when i cut the gear for my Barnes 4 1/2 thread dial that i made , i calculated i needed near a 32 pitch gear ( EXACT pitch not necessary & near impossible to cut in home shop.....,it just needs to roll in mesh .slack being taken up ..even xact FORM not necessary ) .....i happened to have a 30 pitch cutter , & cut a slightly smaller gear blank than "spec" ,.... the larger spaces & thinner teeth allowed a nice easy rolling action....

lathe bits carefully ground to fit a gear used as a gauge , work quite well ..

doc

Thanks for the confirmation Doc, when I started this project those where almost my exact thoughts, slow speed and adjustment made it easy, and I made two cutters, one each for the small and larger gear.

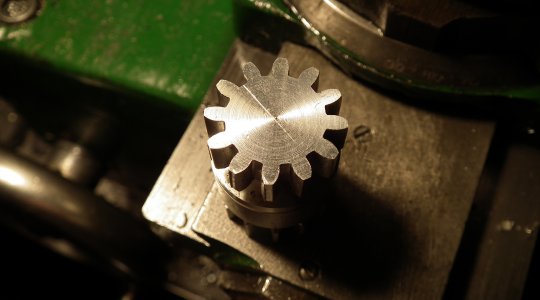

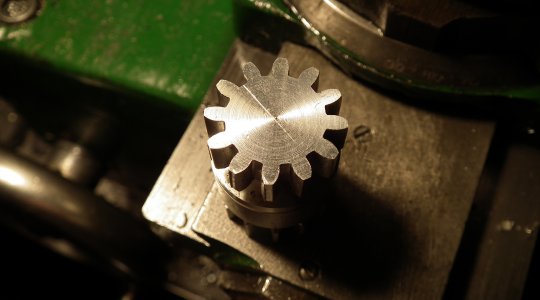

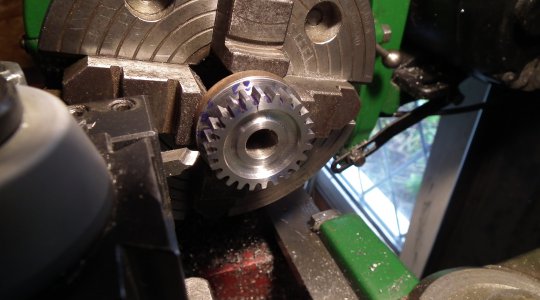

I broached a couple of very good practice gears in ally, cut off tool, then form tool, took around 1/2 hr to do .

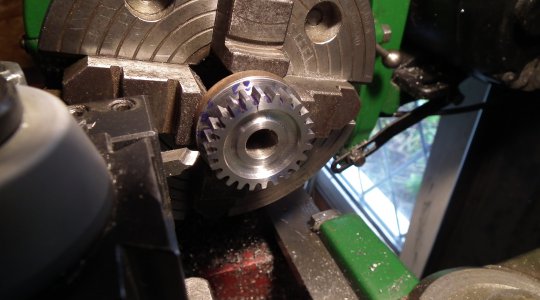

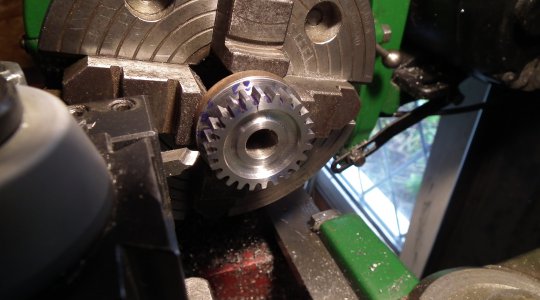

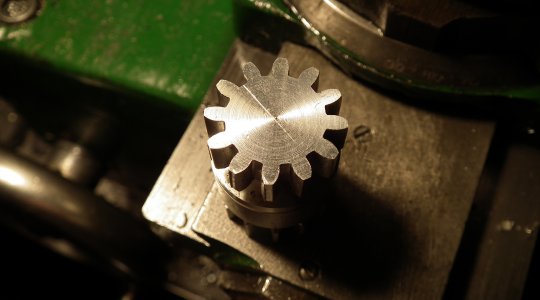

Then I made the one shown before in free cutting steel which engages the rack and it works very well, here with the shaft relieved to clear the lead screw, this one's a keeper.

The larger gear for the other end of that shaft suffered when the indexing pin worked out of the bull gear and I didn't notice and spoiled a couple of teeth, a bit disheartening as it was the last few teeth..the whole gear train when assembled works OK but the couple of bad teeth and the skinny teeth mesh rather sloppy and make an intermittent roughness I don't like..

The other shaft/gear on the left for the apron crank handle) looks good but teeth are too skinny which makes them klonk when in use.

I dont know but the gear you made looks pretty good it is such a slow turning gear I dont think you would have much problem with the one you made if I had that gear laying around in my shop I would use it, I need to cut one for mine as well I just have not got around to it. Ray

Ray that one is OK but all subsequent ones had faults I wasn't happy with.

An easy way to check the pressure angle of a gear is to roll it in some modeling clay. That will generate a tooth form with straight sides. Then just measure the angle of the tooth formed in the clay.

Another good tip jererp, we badly need this sort of info!

The gear you made looks great to me. If I could do that good I wouldn't be trying to get the local gear shop to make one for me. I need the gear that goes on the cross feed screw. When I bought my lathe it was gone, along with the cross feed dial and pinion. I've been trying to make all of this but I thought I could probably purchase the little gear easier than I could make one. However, now that I have been quoted $275 for the little 17 tooth gear, I may need to re-think. How did you make the one you have? Jimmy

I used my lever operated compound Jimmy ...

http://www.hobby-machinist.com/showthread.php?t=19267

The problem with broaching gears in steel is that the cutting edge of the cutter in contact with the work increases as it goes deeper, this really finds any looseness in the gibs/lead screws/indexer/chuck drive pin etc. Even with all gibs locked this can cause chatter which can alter the indexing if care is not taken, once the chatter marks are there it's almost impossible to cut that gear smooth again before cutting too deep.

I could use the tools I made in a flycutter but that really gives the bull gear drive pin a workout, don't want it to get worn out! For that reason I'm thinking of using a involute cutter unless you guys have a better idea.........One of my self imposed disciplines is to make everything as near to free as humanly possible, so far I have spent almost a couple of quid on this..

Bernard