- Joined

- Jun 12, 2014

- Messages

- 4,810

Chinese gear head mill with stock oil, I went to a synthetic gear head oil by Amsoil. The difference was significant.What oil were you using before you gained 100 rpm, less foaming and cooler running?

Please show me one lathe or mill manufacture that states motor oil can be substituted for gear oil in their machine. Moisture and condensation is always an issue, especially in more humid climates. Many machines have a crankcase breather tube, so they are constantly pulsating air into the gear case.

When you drain the oil, you often find a lot of particulates in the oil and it can be quite dirty, so if you don't mind having all this stuff floating in the oil, then go for the detergent oil. There are plenty of testimonials about the use of motor oils in lathes mills, etc. both pro and con. The There is enough reports in other forums about the machine running hotter (due to increase frictional shear) with the motor oil, that I still think one should stick with the proper recommended oil, as opposed to saving a dollar or two here or there. The other factor, just like in motors, change you oil at the recommended intervals.

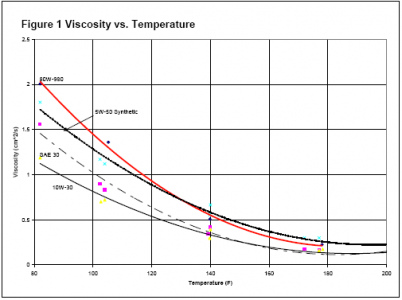

I still disagree on the use of motor oil in gearheads, because the motor oil viscosity is designed around the operating temperatures of motors, gear oils are designed around much lower operating temperatures (usually 40C). The viscosity difference can be very significant. Putting 10W motor oil in your lathe might be closer to putting ISO100 at the operating temperature in a lathe. The difference in viscosity for a motor oil at the two operating temperatures is about 3X. Per Amsoil blurb: "Because an internal combustion engine has an oil pump and lubricates the bearings with a hydrodynamic film, extreme-pressure additives such as those used in gear oils are not necessary."

http://www.amsoil.com/newsstand/auto-and-light-truck/articles/dont-forget-the-gear-oil/?zo=34396

Gearhead oil was black and full of metal particles after 1 year.

Last edited:

Steve Shannon, P.E.

Steve Shannon, P.E.