I figured I'd do my first intro post as a project I just finished up. I have a Bolton benchtop mill (rong fu clone) and a little harbor freight 9x19 lathe. I do knifemaking and gunbuilding as a hobby and have lots of other smaller equipment including forges, melting furnaces, Viking age iron smelting furnace built from local clay...you know, the usual stuff everyone has in the backyard!

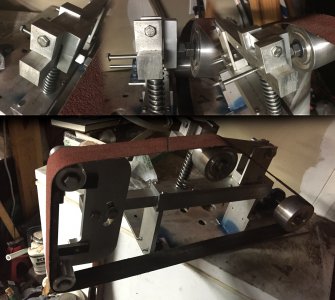

My Grizzly knifemaker's belt grinder finally crapped out on me back in August. I've been "meaning to" get around to building a new one for the last 8 years or so. This time when I went to band aid the Grizzly, it seized up...for good. The bearings were gone, and looked to have been gone for some time now. The cast iron ring on the upright base was the only thing holding the shaft in place! No wonder it was wobbling a bit!

Good thing is I've been scrounging pieces for several years for a new one. I loved the KMG grinders from Beaumont Metalworks, but just couldn't get myself to drop over $1k on something I knew I could do myself.

I picked up blocks of aluminum off ebay as funds were available. Most of these came from Stoner's Tools (6061dude).

The wheels I picked up both on ebay and from Beaumont Metalworks.

I got the tracking and drive wheels off ebay for 35 and 45 respectively.

The platen assembly I also got from BM.

I got the pillow block bearings off ebay.

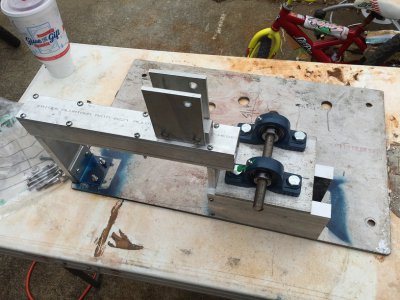

The base plate aluminum I picked up years ago from my old lab scrap.

The 1 hp motor came from Harbor Freight.

I have a youtube video of it finished and running...

My Grizzly knifemaker's belt grinder finally crapped out on me back in August. I've been "meaning to" get around to building a new one for the last 8 years or so. This time when I went to band aid the Grizzly, it seized up...for good. The bearings were gone, and looked to have been gone for some time now. The cast iron ring on the upright base was the only thing holding the shaft in place! No wonder it was wobbling a bit!

Good thing is I've been scrounging pieces for several years for a new one. I loved the KMG grinders from Beaumont Metalworks, but just couldn't get myself to drop over $1k on something I knew I could do myself.

I picked up blocks of aluminum off ebay as funds were available. Most of these came from Stoner's Tools (6061dude).

The wheels I picked up both on ebay and from Beaumont Metalworks.

I got the tracking and drive wheels off ebay for 35 and 45 respectively.

The platen assembly I also got from BM.

I got the pillow block bearings off ebay.

The base plate aluminum I picked up years ago from my old lab scrap.

The 1 hp motor came from Harbor Freight.

I have a youtube video of it finished and running...