- Joined

- Jul 4, 2014

- Messages

- 156

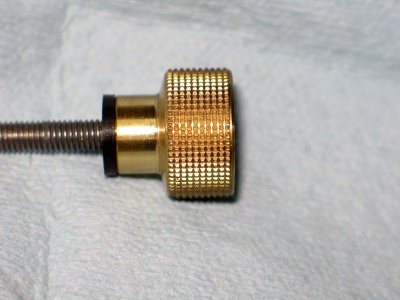

Prasad, I tried to post pics of my knurler before but was unable to do so until Nelson and Robert got to work on the problem. Now it seems to work and I can show you a simple tool I made for my Sherline lathe. It is mounted to the rear of the cross slide and will transfer to my larger lathe by changing the mount. This knurler has produced beautiful knurls in mild steel, stainless, aluminum, brass and Delrin. In most cases, it will create a full-pattern knurl on the first pass if I do my job.

View attachment 113315 View attachment 113316 View attachment 113317

I hope this gives you some ideas if you decide to make one of your own.

Edit: I forgot to add that it will knurl from zero out to 2-1/8" OD and despite having a hex shaped shank on the main screw, it tightens with simple hand pressure. Cost was almost nothing except the knurls - just stuff I had laying around the shop.

Thank you Mike. Pictures are clear to me. This will be one of my projects. I have printed the photos for reference later. Thanks again

Prasad