-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Knurling with Hand Tools

- Thread starter sign216

- Start date

- Joined

- Jan 4, 2021

- Messages

- 1,801

[Edit: Sorry, I read further down the thread and see that you already found this one; at least you now know a little more info and that it will do drill rod – Charlie]Anyone have experience knurling w hand tools? Any issues or things to keep in mind with the different tool styles ?

Occaisionally I have small pins (1/8 to 3/16") that need knurling on the end. The hand tools appear to be an easy fix, if they work as advertised.

I picked this up a few years ago on eBay from the guy that made it (see previous post/thread):

Worked well on 3/8" drill rod:

Advertised to work down to 1/4" and it might do 3/16", but not 1/8". It weights 3+ lbs., is a little awkward on small diameter rod and can't get too close to the end (it works not unlike a pipe cutter: crank the handle, roll around the rod, crank/roll & repeat). However, it may give you some ideas.

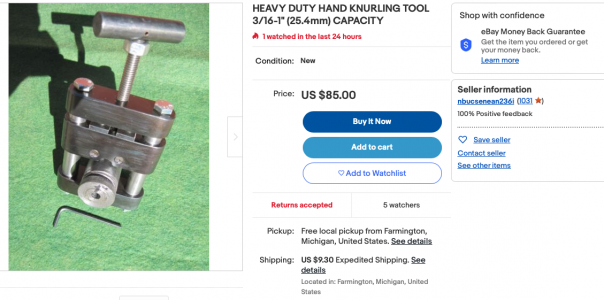

Just checked and the guy is still making these, and has a smaller version that will go down to 3/16". You can try reaching out to him and see if it would do 1/8" (or if he'll make you one that will):

Straight knurling wheels, but you can get diamond ones.

Good luck!

Last edited:

[Edit: Sorry, I read further down the thread and see that you already found this one; at least you now know a little more info and that it will do drill rod – Charlie]

I picked this up a few years ago on eBay from the guy that made it (see previous post/thread):

View attachment 441786

Worked well on 3/8" drill rod:

View attachment 441787

Advertised to work down to 1/4" and it might do 3/16", but not 1/8". It weights 3+ lbs., is a little awkward on small diameter rod and can't get too close to the end (it works not unlike a pipe cutter: crank the handle, roll around the rod, crank/roll & repeat). However, it may give you some ideas.

Just checked and the guy is still making these, and has a smaller version that will go down to 3/16". You can try reaching out to him and see if it would do 1/8" (or if he'll make you one that will):

View attachment 441792

Straight knurling wheels, but you can get diamond ones.

Good luck!

ChazzC,

Thanks for the report. It knurled that steel well. My smaller rod is actually a shade less than 1/8" so I'll see if he can work w that.

Joe

Works on c1215 steel. That is not very hard.

I had another thought. Maybe you could adapt a tube cutter

Jimsehr, that's a great idea; converting a tube cutter into a knurler. Looking at my tube cutter, the blade is readily replacable, but there's only about 1/16" room, lengthwise, to fit a knurler wheel. How long are the wheels in your unit?

Jimsehr's idea of using a copper pipe cutter, and replacing the cutting wheel w a knurler wheel, worked!

Most knurling wheels were too wide, but on Ebay I found one that was 3/16" wide, just a little more than the pipe cutter gap. I opened the pipe cutter gap w a fluted steel cutter on a dremel, and also dressed the opening w a coarse file. Worked very well. Note that the dremel's grinding stone was too slow in removing material, but the HSS cutter was very fast. I was surprised that the little pipe cutter had the force to impress the tool steel pin, but it worked well.

Most knurling wheels were too wide, but on Ebay I found one that was 3/16" wide, just a little more than the pipe cutter gap. I opened the pipe cutter gap w a fluted steel cutter on a dremel, and also dressed the opening w a coarse file. Worked very well. Note that the dremel's grinding stone was too slow in removing material, but the HSS cutter was very fast. I was surprised that the little pipe cutter had the force to impress the tool steel pin, but it worked well.

Attachments

- Joined

- Jan 4, 2021

- Messages

- 1,801

Looks good. If you replace the two rollers with opposite direction knurls you should be able to get full diamonds.Jimsehr's idea of using a copper pipe cutter, and replacing the cutting wheel w a knurler wheel, worked!

Most knurling wheels were too wide, but on Ebay I found one that was 3/16" wide, just a little more than the pipe cutter gap. I opened the pipe cutter gap w a fluted steel cutter on a dremel, and also dressed the opening w a coarse file. Worked very well. Note that the dremel's grinding stone was too slow in removing material, but the HSS cutter was very fast. I was surprised that the little pipe cutter had the force to impress the tool steel pin, but it worked well.

View attachment 442803