- Joined

- Oct 6, 2010

- Messages

- 699

A while back I scored a KO Lee B600 tool & cutter grinder at the local scrap yard. I posted about it in the General forum section (http://www.hobby-machinist.com/show...on-needed-for-cleaning-and-checkout&highlight) and asked for any information that might be available from members. That post did not get moved to the grinder section so I thought I would start new here with progress reports.

I have been looking for any information and tooling for possible use in getting the grinder into a useable condition. I figured from the beginning that I would have to make and/or adapt tooling intended for other machines or it could take forever watching fleece-bay for the correct tooling at a price I could afford. A kind gentleman here in middle Tennessee loaned me some tooling that he got with a KO Lee t&c grinder he received in a bunch of equipment traded for. Most of the fixture tooling was not KO Lee and I am not sure that the few KO Lee parts borrowed are the same as the OEM parts for mine since they don’t look like the parts in the manual I have. One borrowed fixture was a B988 for grinding circular cutters. It is probably for a later model KO Lee grinder but I did take photos and dimensional information in case I needed to make something similar. Photo 1 shows what that circular cutter sharpening fixture looked like; some parts for indexing the cutter are missing.

As mention in first thread I purchased a universal vise from Jeff at Tools4Cheap. It is similar to the KO Lee model B789 universal holding device shown in the manual for the KO Lee B600 series grinders and should work fine. After I received the “Univise” from Jeff a friend of mine found a work holding device at the same scrap yard that looks like it probably was part of the stuff scraped along with the grinder. It is shown in Photo 2 and no manufacturer ID on it. Looking back I probably could get by without purchasing the new “Univise” but I will keep both, you can’t have too many tools.

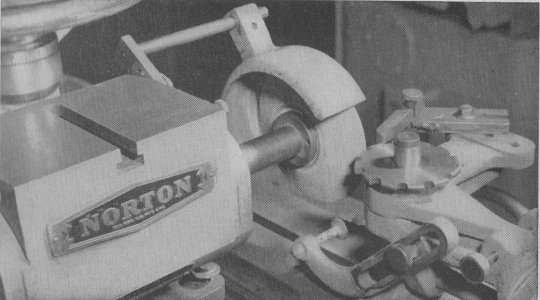

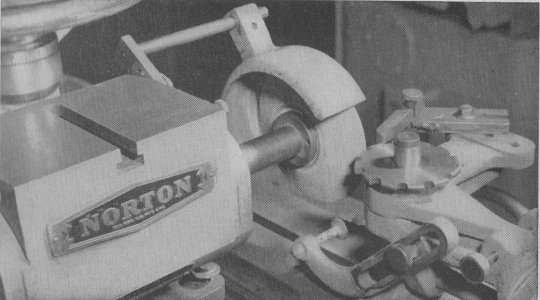

A few days ago I was in the scrap yard and saw a great looking mechanism that rang a bell. I remembered seeing it somewhere before. I could not sleep last night so I picked up an old copy of Norton Abrasives’ “Tool Room Grinding” and started looking through it and on page 45 I saw the mechanism, it was a Norton circular form cutter sharpening fixture. Today I went by the scrap yard to try and locate a piece of material to make an abrasive wheel adapter (another project) and while there purchased the fixture. It is probably too big for my grinder but sure is cool. I will see if I can adapt it or maybe trade it for one more in proportional to my grinder. Photo #3 shows the Norton fixture as found. It should clean up nicely. Photo #4 is from the Norton handbook and shows the Norton fixture in use.

I have started cleaning up the grinder but stopped as I did not want to mess up the wooden furniture dolly it is setting on. I need to make something more durable to roll it around on while cleaning and painting…. another project. I did get some of the grim off the table and got a little oil into the motor bearings which sounded dry when the motor was tested. I may have to replace the bearings at some point but not now.

Not sure about photo labels since the first preview jumbled them. Hopefully I can learn to do this better and meanwhile you can figure out which photos are which.

That’s all for now.

Benny

I have been looking for any information and tooling for possible use in getting the grinder into a useable condition. I figured from the beginning that I would have to make and/or adapt tooling intended for other machines or it could take forever watching fleece-bay for the correct tooling at a price I could afford. A kind gentleman here in middle Tennessee loaned me some tooling that he got with a KO Lee t&c grinder he received in a bunch of equipment traded for. Most of the fixture tooling was not KO Lee and I am not sure that the few KO Lee parts borrowed are the same as the OEM parts for mine since they don’t look like the parts in the manual I have. One borrowed fixture was a B988 for grinding circular cutters. It is probably for a later model KO Lee grinder but I did take photos and dimensional information in case I needed to make something similar. Photo 1 shows what that circular cutter sharpening fixture looked like; some parts for indexing the cutter are missing.

As mention in first thread I purchased a universal vise from Jeff at Tools4Cheap. It is similar to the KO Lee model B789 universal holding device shown in the manual for the KO Lee B600 series grinders and should work fine. After I received the “Univise” from Jeff a friend of mine found a work holding device at the same scrap yard that looks like it probably was part of the stuff scraped along with the grinder. It is shown in Photo 2 and no manufacturer ID on it. Looking back I probably could get by without purchasing the new “Univise” but I will keep both, you can’t have too many tools.

A few days ago I was in the scrap yard and saw a great looking mechanism that rang a bell. I remembered seeing it somewhere before. I could not sleep last night so I picked up an old copy of Norton Abrasives’ “Tool Room Grinding” and started looking through it and on page 45 I saw the mechanism, it was a Norton circular form cutter sharpening fixture. Today I went by the scrap yard to try and locate a piece of material to make an abrasive wheel adapter (another project) and while there purchased the fixture. It is probably too big for my grinder but sure is cool. I will see if I can adapt it or maybe trade it for one more in proportional to my grinder. Photo #3 shows the Norton fixture as found. It should clean up nicely. Photo #4 is from the Norton handbook and shows the Norton fixture in use.

I have started cleaning up the grinder but stopped as I did not want to mess up the wooden furniture dolly it is setting on. I need to make something more durable to roll it around on while cleaning and painting…. another project. I did get some of the grim off the table and got a little oil into the motor bearings which sounded dry when the motor was tested. I may have to replace the bearings at some point but not now.

Not sure about photo labels since the first preview jumbled them. Hopefully I can learn to do this better and meanwhile you can figure out which photos are which.

That’s all for now.

Benny