- Joined

- Dec 8, 2013

- Messages

- 2,651

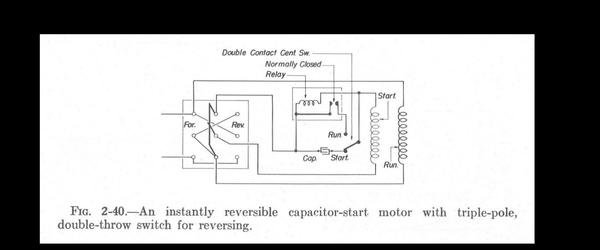

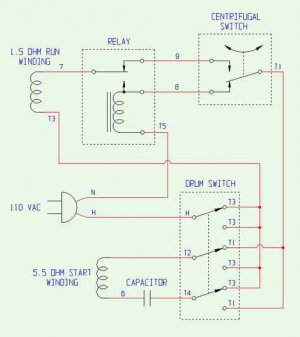

I don't see that this circuit is going to work. When you throw the switch from forward over to reverse it appears to me that you end up with both windings energized and the capacitor out of the circuit. This will result in the motor continuing to run in the same direction while drawing more current.

I think this circuit will work, but it isn't the same as the other.

The motor is special at least in that it has a double-throw centrifugal switch.