Haven't posted in a while, Just a couple of project photos.

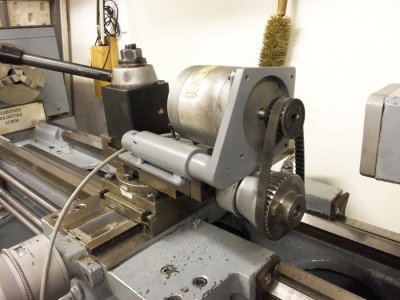

Photo 1 is an adapter I made for my Tool Post Grinder to grind the jaws on my lathe. It is made from a scraped shaft from a heavy equipment gear box.

The collet and collet nut are from a die grinder.

Got the run out on the chuck from 0.020" to 0.0015"

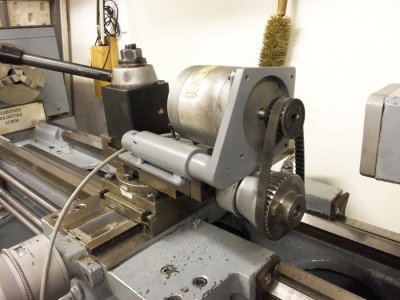

Photo 2 is a power feed for the lathe compound. (I did a couple of long tapered holes a few months back. The first one wasn't that bad but when I made the a second one, it did a real number on my rotator cuff ) The frame is made from scrape, I already had the motor, motor controller and pulleys.

Photo 1 is an adapter I made for my Tool Post Grinder to grind the jaws on my lathe. It is made from a scraped shaft from a heavy equipment gear box.

The collet and collet nut are from a die grinder.

Got the run out on the chuck from 0.020" to 0.0015"

Photo 2 is a power feed for the lathe compound. (I did a couple of long tapered holes a few months back. The first one wasn't that bad but when I made the a second one, it did a real number on my rotator cuff ) The frame is made from scrape, I already had the motor, motor controller and pulleys.