- Joined

- Nov 6, 2015

- Messages

- 24

Hi,

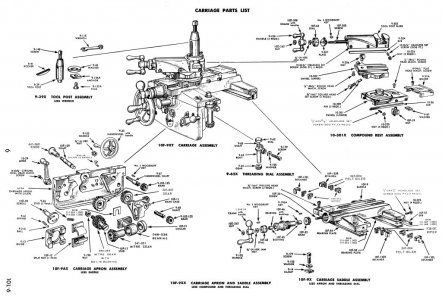

So in this rebuild process I have discovered there were a couple missing parts. One is the shim in the Apron (pat 10F-85). The lathe worked fine when I took it apart, but there is no shim, and the parts diagram calls for one. Any guidance on that subject? Also I am trying to find a part number for the screws that hold the rack on the bed. I broke on during disassembly and don't see a part number on the exploded diagram. Also, What does the plunger in the apron do exactly? The spacer near the top of the plunger is missing, I have already odered a replacement, but I don't understand the operation of that spring, spacer, and plunger. I've gathered the plunger contacts the split nut scroll, but to what end? I would be grateful for any help!

Regards,

Vulcan

So in this rebuild process I have discovered there were a couple missing parts. One is the shim in the Apron (pat 10F-85). The lathe worked fine when I took it apart, but there is no shim, and the parts diagram calls for one. Any guidance on that subject? Also I am trying to find a part number for the screws that hold the rack on the bed. I broke on during disassembly and don't see a part number on the exploded diagram. Also, What does the plunger in the apron do exactly? The spacer near the top of the plunger is missing, I have already odered a replacement, but I don't understand the operation of that spring, spacer, and plunger. I've gathered the plunger contacts the split nut scroll, but to what end? I would be grateful for any help!

Regards,

Vulcan