- Joined

- Jan 23, 2019

- Messages

- 30

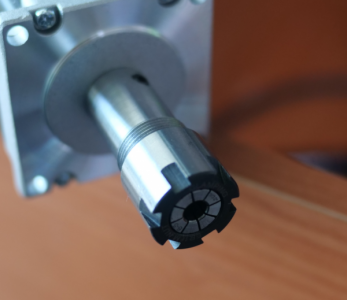

i needed an er16 collet chuck for my stepper motor.

purchased two from ebay: "er16 collet chuck motor extension"

i've had much luck with chinese tools, but this time... it was a terrible experience.

the specs said if i purchased 8mm ID for motor shaft, I would receive 7.98mm shaft so i could induction heat it, then put it on the shaft

however, i recieved 8.1mm oversized hole, so i couldn't use it... too much runout.

took over a month for it to arrive, wasn't going to wait again.

based on google and forums er collet chucks have 8 degree internal taper angle

my compound was not gonna have the accuracy required,

so i used a bevel protractor to get the precision within 0.1 degrees, which for ER collets is enough

even greater precision could be set, if i purchased electronic bevel protractor, but it would cost me over $600 for quality one.

i just went with vernier one, which wasn't too bad.

below is the link to the making vid of this collet holder

feel free to comment

attached is the photo of it

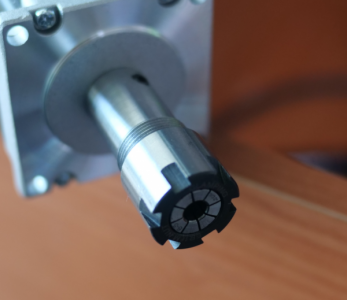

purchased two from ebay: "er16 collet chuck motor extension"

i've had much luck with chinese tools, but this time... it was a terrible experience.

the specs said if i purchased 8mm ID for motor shaft, I would receive 7.98mm shaft so i could induction heat it, then put it on the shaft

however, i recieved 8.1mm oversized hole, so i couldn't use it... too much runout.

took over a month for it to arrive, wasn't going to wait again.

based on google and forums er collet chucks have 8 degree internal taper angle

my compound was not gonna have the accuracy required,

so i used a bevel protractor to get the precision within 0.1 degrees, which for ER collets is enough

even greater precision could be set, if i purchased electronic bevel protractor, but it would cost me over $600 for quality one.

i just went with vernier one, which wasn't too bad.

below is the link to the making vid of this collet holder

feel free to comment

attached is the photo of it