-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Milling Arbor?

- Thread starter darkzero

- Start date

- Joined

- Apr 23, 2013

- Messages

- 4

Hi Will and All,

Though they could be used in a lathe, they are made for 'Horizontal milling machines' particularly the long one which relies on a supporting 'over-arm' which is a heavy supporting bracket to stop the non taper end from being deflected in use.

The arbors can take saws, but they will also take much chunkier cutting wheels (see milling cutters on Google)- because a horizontal miller is like a heavy duty lathe with a short bed known as a table that can be lifted up and down over what for a lathe would be a huge swing they can be very flexible - their supporting over-arm means that they can remove a lot of metal in one go: much more than a lathe...

The rings on the arbor allow the cutter to be spaced out anywhere along the arbors length.

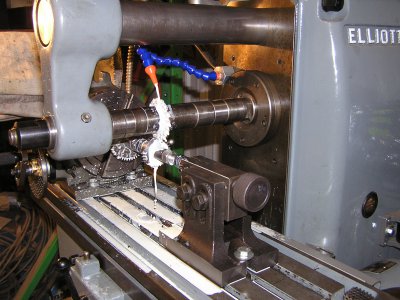

Take a look for horizontal milling machines on the net - they are very powerful tools - I own an English built Elliott 181...

Regards,

Denver.

Though they could be used in a lathe, they are made for 'Horizontal milling machines' particularly the long one which relies on a supporting 'over-arm' which is a heavy supporting bracket to stop the non taper end from being deflected in use.

The arbors can take saws, but they will also take much chunkier cutting wheels (see milling cutters on Google)- because a horizontal miller is like a heavy duty lathe with a short bed known as a table that can be lifted up and down over what for a lathe would be a huge swing they can be very flexible - their supporting over-arm means that they can remove a lot of metal in one go: much more than a lathe...

The rings on the arbor allow the cutter to be spaced out anywhere along the arbors length.

Take a look for horizontal milling machines on the net - they are very powerful tools - I own an English built Elliott 181...

Regards,

Denver.

- Joined

- Nov 27, 2012

- Messages

- 7,855

Denver, thanks for the reply.

Here's the only horizontal mill I have ever used, a K&T S-12. I just remember that the arbors were big & required two hands to hold them, emphasis was to be very careful not damage the tapers.

But the ones I posted are much smaller & as you can see they have R8 tapers. So these are actually for small bench top sized horizontal mills? Had no idea they used R8 tapers but then again I never paid any attention. The top one pictured above seems like it would be for a horizontal mill but not so much the shorter ones on bottom.

Here's the only horizontal mill I have ever used, a K&T S-12. I just remember that the arbors were big & required two hands to hold them, emphasis was to be very careful not damage the tapers.

But the ones I posted are much smaller & as you can see they have R8 tapers. So these are actually for small bench top sized horizontal mills? Had no idea they used R8 tapers but then again I never paid any attention. The top one pictured above seems like it would be for a horizontal mill but not so much the shorter ones on bottom.

Last edited:

- Joined

- Apr 23, 2013

- Messages

- 4

Hi Will and All,

You are probably right about R8 tapers - it is common for the smallest horizontal millers to use a 3 or even 2 Morse taper, however they were replaced by int30 or int40 on later versions - note mine's an in30...

R8 usually means Bridgeport - they invented the standard - usually for their vertical quill machines - I don't know whether they ever did a horizontal with an R8 drive, but they did make a right angle drive and 'over-arm' support kit for simulating a horizontal drive on their vertical milling machines - Vertex certainly still make a copy of this conversion kit for int40 drive machines - I have one with the idea of using it as a vertical quill on my horizontal miller. The short stubs would make sense in their vertical millers using slitting saws.

Lovely pictures you've found there - that Elliott could be a similar model to my 181 - the top one's a beauty - with a double round bar over-arm - a bit big for my work-shop though!

Regards,

Denver.

You are probably right about R8 tapers - it is common for the smallest horizontal millers to use a 3 or even 2 Morse taper, however they were replaced by int30 or int40 on later versions - note mine's an in30...

R8 usually means Bridgeport - they invented the standard - usually for their vertical quill machines - I don't know whether they ever did a horizontal with an R8 drive, but they did make a right angle drive and 'over-arm' support kit for simulating a horizontal drive on their vertical milling machines - Vertex certainly still make a copy of this conversion kit for int40 drive machines - I have one with the idea of using it as a vertical quill on my horizontal miller. The short stubs would make sense in their vertical millers using slitting saws.

Lovely pictures you've found there - that Elliott could be a similar model to my 181 - the top one's a beauty - with a double round bar over-arm - a bit big for my work-shop though!

Regards,

Denver.

- Joined

- Nov 27, 2012

- Messages

- 7,855

Hi Will and All,

You are probably right about R8 tapers - it is common for the smallest horizontal millers to use a 3 or even 2 Morse taper, however they were replaced by int30 or int40 on later versions - note mine's an in30...

R8 usually means Bridgeport - they invented the standard - usually for their vertical quill machines - I don't know whether they ever did a horizontal with an R8 drive, but they did make a right angle drive and 'over-arm' support kit for simulating a horizontal drive on their vertical milling machines - Vertex certainly still make a copy of this conversion kit for int40 drive machines - I have one with the idea of using it as a vertical quill on my horizontal miller. The short stubs would make sense in their vertical millers using slitting saws.

Lovely pictures you've found there - that Elliott could be a similar model to my 181 - the top one's a beauty - with a double round bar over-arm - a bit big for my work-shop though!

Regards,

Denver.

Thanks again Denver, great info & really explains a lot! Glad they are not something that I "need".

I actually took those photos from my phone & that was me cutting that block. I took the conventional machine shop courses at the local college for a couple of years for the heck of it, very glad I did. That horiz mill was nice, powerful & rigid, had power feed too. But then again it was the only horizontal mill I have ever used so I have no other experience for a comparison.

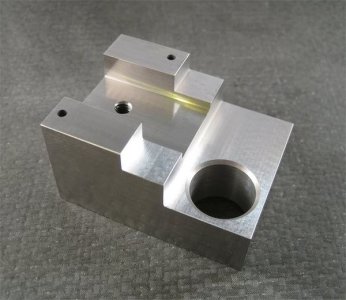

I used it to make one of the projects which was some sort of block. Not sure if it actually serves any purpose (I kept forgetting to ask) but it taught us various ops as well as the surface grinder. Everyone prefered to use the Bridgeports & seemed to be scared of the horizontal mills so the BPs were always occupied. But I was always happy to use any machine available & it was much quicker on the horizontal mill.

EDIT:

Oops, my mistake. In that photo I was making the block for a V-Block but the other block I machined in that horizontal mill as well.

Excuse the dust, it's been sitting on the shelf. Didn't get to fully finish this one though, the block was supposed to ground but I still got an A for it.

Last edited:

- Joined

- Aug 21, 2011

- Messages

- 55

Nice work on the V-block & the "unknown" block. It's a shame so many people overlook the beauty of horizontal mills in favor of the Bridgeport style. My first mill was a horizontal, a small Burke and I liked it so much my next one was K & T 2-H and that was like 40 years ago.

- Joined

- Apr 23, 2013

- Messages

- 4

Hi Will and All,

Horizontal millers are far more robust than vertical quill millers - hence they are capable of cutting deeper and faster than any other type of machine - grinders, shapers lathes included - their strength is also their weakness though: in order to move the work under the cutter, the entire table has to be moved, which means shifting a lot of weight at once causing the operation to be low on feedback and feel - it is quite easy to drive the table too fast into the work and finish up getting the whole lot juddering - only pleasant for those that like simulating earthquakes.

The vertical millers on the other hand, that lose out on direct power and accuracy, do give much more feel, so it's easier to get used to them. The cutting wheels for horizontal millers are very expensive as well and almost impossible to resharpen manually. This does has the advantage of there being a lot of usable second hand cutters about though making the horizontal machines more viable for enthusiasts. On this front, I'm very lucky insofar that I've just got hold of a tool grinding rig cheaply that should allow me to sharpen my own cutters.

Due to the fact that surface grinders are roughly the same build as horizontal millers, some people have been known to put grind stones directly into their millers which is a very dangerous thing to do - the reason is that where the HSS cutters will take a certain amount of abuse, when a work item is offered too abruptly into a stone the result is a broken wheel because of the rigidity of the horizontal mill arbor - surface grinders don't allow this - naturally taken to extremes it would still be possible to destroy a cutting wheel in an abused miller with catastrophic results. Hence the fear that people have of horizontal millers - I love mine though, at least as much as my Boxford (a UK taper bearing, v-belted, ten inch swing, precision, Southbend clone).

They can be used for delicate jobs like cutting slots with end mills or making small brass pinions:

Regards,

Denver.

Horizontal millers are far more robust than vertical quill millers - hence they are capable of cutting deeper and faster than any other type of machine - grinders, shapers lathes included - their strength is also their weakness though: in order to move the work under the cutter, the entire table has to be moved, which means shifting a lot of weight at once causing the operation to be low on feedback and feel - it is quite easy to drive the table too fast into the work and finish up getting the whole lot juddering - only pleasant for those that like simulating earthquakes.

The vertical millers on the other hand, that lose out on direct power and accuracy, do give much more feel, so it's easier to get used to them. The cutting wheels for horizontal millers are very expensive as well and almost impossible to resharpen manually. This does has the advantage of there being a lot of usable second hand cutters about though making the horizontal machines more viable for enthusiasts. On this front, I'm very lucky insofar that I've just got hold of a tool grinding rig cheaply that should allow me to sharpen my own cutters.

Due to the fact that surface grinders are roughly the same build as horizontal millers, some people have been known to put grind stones directly into their millers which is a very dangerous thing to do - the reason is that where the HSS cutters will take a certain amount of abuse, when a work item is offered too abruptly into a stone the result is a broken wheel because of the rigidity of the horizontal mill arbor - surface grinders don't allow this - naturally taken to extremes it would still be possible to destroy a cutting wheel in an abused miller with catastrophic results. Hence the fear that people have of horizontal millers - I love mine though, at least as much as my Boxford (a UK taper bearing, v-belted, ten inch swing, precision, Southbend clone).

They can be used for delicate jobs like cutting slots with end mills or making small brass pinions:

Regards,

Denver.

But the ones I posted are much smaller & as you can see they have R8 tapers. So these are actually for small bench top sized horizontal mills? Had no idea they used R8 tapers but then again I never paid any attention. The top one pictured above seems like it would be for a horizontal mill but not so much the shorter ones on bottom. [/IMG]

If the taper is R8, it's probably for the horizontal attachment for a Bridgeport. There's a support that clamps onto the bottom of the ram's dovetail and holds the outboard end of the arbor. Stub arbors also work in the horizontal attachment. This is for lighter milling than you'd do on a real horizontal mill.

they make a right angle attachment for bridgies and clones to turn them into a horizontal mill. kind of a work around, but good if you only have room for one machine. if you used horizontals, you know that they can get the the metal out of the way faster than a comparable sized vertical. horizontals are just plain rigid, and super cheap. Even a little atlas horizontal will suprise you with its capability.