In roadie33's thread "New to me C4raftsman Commercial 12x36" he discussed possibly broaching a keyslot in a replacement gear. I offered a solution for folks who do not have a broach set (which can be rather costly) at post # 7.

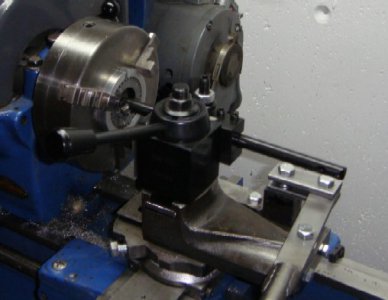

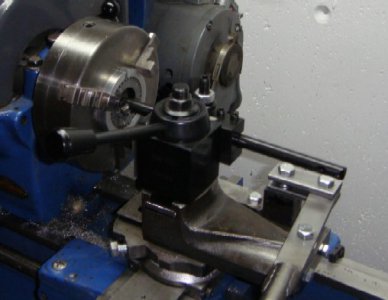

Here I am posting a more complete photo essay of how I modified a tool rest compound to be operated with a hand lever do do the broaching using a boring bar to hold the custom ground cutter.

Here I am posting a more complete photo essay of how I modified a tool rest compound to be operated with a hand lever do do the broaching using a boring bar to hold the custom ground cutter.