- Joined

- Mar 10, 2015

- Messages

- 309

Hey guys wanted to bounce something out there. See if anyone has made mods and / or changed the drill quill lever on a RF-45 clone or similar mills ,

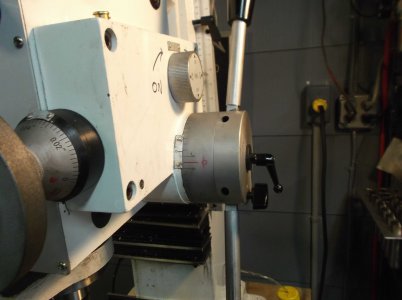

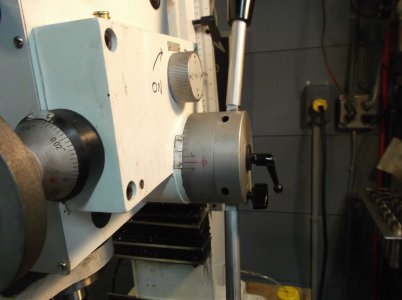

Recently I purchased a PM932 PDF its a 9x32 mill with power down feed option. I have found that the lower quill Drill down feed lever gets in way of work . Since it has two feed levers 180 deg apart even in the up most position the lower lever can interfere with work in vice and or work on the table .

Since I have a PDF model I plan on taking apart see if I can do a mod for the down feed assemblythat may accommodate a better handle position and operation of engagement in the down feed . Right now the only thing I see shorting the lower handle and making new knobs .

However love to see someones fix if they already worked this out esp including PDF operation mechanics .

Is there anyone with similar mill done these sort of mods ? If so can ya share perhaps post pic of how ya made it better .Ps If I dont get many responses, guess ill post pics my resolution when I get around to doin... thanksguys