-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My G4000

- Thread starter Analias

- Start date

- Joined

- Oct 13, 2012

- Messages

- 175

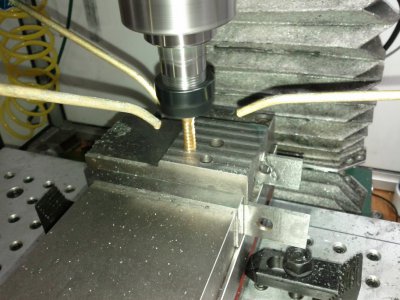

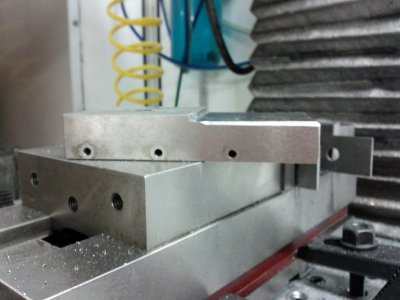

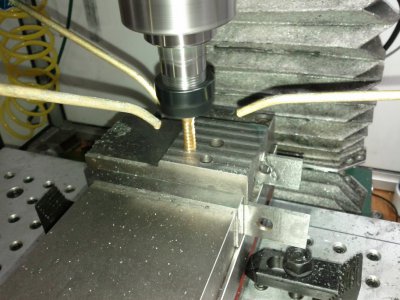

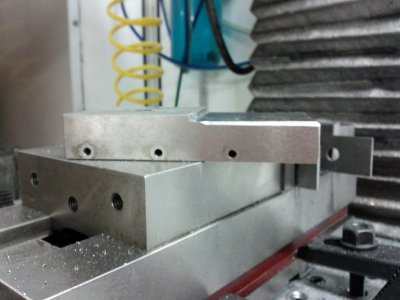

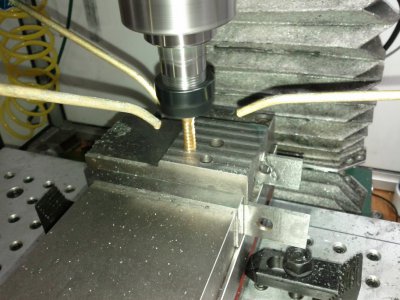

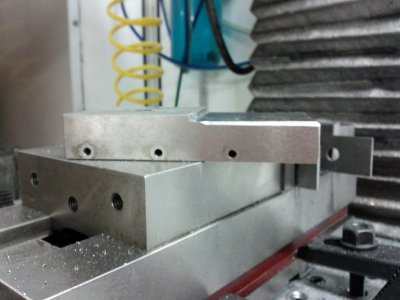

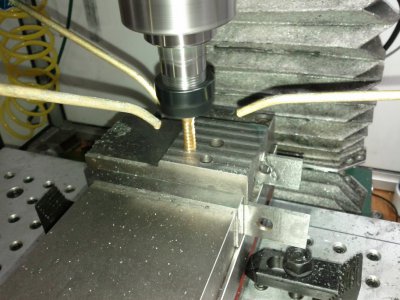

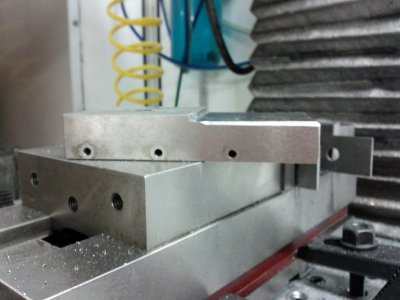

Well that went well. I measured what I needed to take off the boss and created a quick g-code file using the New Fangled's Mill Wizard. Everything ran fine and I removed .140" off the boss. I was able to align the tool tip and the center line off the chuck easily.

I had originally intended to take down the whole boss, but when the lock ping hole appeared during one of the passes, I got curious and double checked the thickness of the material between the top of the boss and the bottom of the hole where the tool post bolt is pressed in. I realized if I took the whole boss down I wouldn't have much left for the tool post. I decided to err on the side of caution and interrupted job when I had removed 0.140". That was enough to allow the tool tip to align with the center line.

Here are the money shots:

Here's some pics I took during the work:

I had originally intended to take down the whole boss, but when the lock ping hole appeared during one of the passes, I got curious and double checked the thickness of the material between the top of the boss and the bottom of the hole where the tool post bolt is pressed in. I realized if I took the whole boss down I wouldn't have much left for the tool post. I decided to err on the side of caution and interrupted job when I had removed 0.140". That was enough to allow the tool tip to align with the center line.

Here are the money shots:

Here's some pics I took during the work:

- Joined

- Oct 13, 2012

- Messages

- 175

I'd see about returning the 1/2" kit and go with 3/8". You would then not have to monkey around with the compound or the QCTP. I know it'll cost to ship it back and forth but in the end you'd be better off.

I seriously considered doing just that. I had originally bought the AXA tool post and the 1/2' tooling thinking I wanted the extra mass to increase rigidity. Since I have three compound slides, one being completely spare, I decided to try modifying one of the compound slides. If it hadn't worked, I always had the option of exchanging for 3/8" tools since I have not used 1/2" tools yet.

I'd like to think the lathe is "mine" now since I had to go through the trouble of modifying it. I look forward to doing several other modifications, like adding a DC motor, tachometer, DROs, carriage and tail stock cam locks, etc.

- Joined

- Nov 27, 2012

- Messages

- 7,912

I doubt you will regret going with 1/2" tools though. It's a good choice IMO cause if you choose to use indexables you'll find a bigger selection of tools available in 1/2" than there is for 3/8".

- Joined

- Oct 13, 2012

- Messages

- 175

I guess my latest updates have been lost due to the forum database being restored recently. I was wondering why I had no feedback from folks who have been helpful in the past

To make a long post short, I got around to mounting some stock on the lathe and doing some test cuts. I was not happy with the results. As you can see, they could use some improving. I did notice quite a play along the axis of the spindle and a more than I like across the axis of the spindle. I plan to remove the main gear and see if I can tighten things up before I resort to pulling the spindle and replacing the bearings.

My second attempt at cutting the 5/8 steel rod improved a bit when I went up a notch on the speed (~600 RPM) and did a bit heavier cut, but still nothing to be proud of.

When cutting the steel rod, the lathe was making a hard "wha-wha-wha-wha..." sound. When I check the run out on the spindle using the three jaw chuck from the HF lathe, it's not too bad at .001 to .0017. As I mentioned the spindle has a lot of play in it when you push-pull on it. It might only need to be tightened up.

If anyone sees what I'm doing wrong I would appreciate being the apprentice to your journeyman. Please enlighten me.

My first cut into a 1.5" Delrin blank.

Some continuing effort, using 5/8 steel rod picked up at Lowes (unknown grade or quality).

To make a long post short, I got around to mounting some stock on the lathe and doing some test cuts. I was not happy with the results. As you can see, they could use some improving. I did notice quite a play along the axis of the spindle and a more than I like across the axis of the spindle. I plan to remove the main gear and see if I can tighten things up before I resort to pulling the spindle and replacing the bearings.

My second attempt at cutting the 5/8 steel rod improved a bit when I went up a notch on the speed (~600 RPM) and did a bit heavier cut, but still nothing to be proud of.

When cutting the steel rod, the lathe was making a hard "wha-wha-wha-wha..." sound. When I check the run out on the spindle using the three jaw chuck from the HF lathe, it's not too bad at .001 to .0017. As I mentioned the spindle has a lot of play in it when you push-pull on it. It might only need to be tightened up.

If anyone sees what I'm doing wrong I would appreciate being the apprentice to your journeyman. Please enlighten me.

My first cut into a 1.5" Delrin blank.

Some continuing effort, using 5/8 steel rod picked up at Lowes (unknown grade or quality).

- Joined

- Oct 13, 2012

- Messages

- 175

I decided to pull the spindle. I had to use a bit of ingenuity to pull it since I don't have a fancy spindle extraction tool. I had to use what I had on hand: a foot long 1/2" carriage bolt, washers, 123 blocks, a long 3/4" I-beam parallel, and some extra 1/8" parallels (for shimming). Out the spindle came.

The bearings look good, as do the races. Hopefully, I just need to put everything back together again and it should work. I've heard that the bearings for the 9x20 are pretty easy to find. Since I have the head stock apart, should I order some and swap them out? Again the originals look good and move freely within.

Before I do put it back together, I want to check the roundness of the spindle where the bearings make contact. I've seen a procedure for that using v-blocks and a DTI, but they also used a precision surface. I don't have one, is that going to be significant problem with the testing? I can't afford the cost and the shipping on the size surface I really want. It will have to wait a bit.

At first glance it looks like I may have a problem removing the chuck side bearing. It did not want to come off. Any suggestions on how to take it off gently? I could do the spindle puller trick in reverse against the spindle and hopefully use a piece of PVC pipe that is close to the same diameter as the bearing washers.

The bearings look good, as do the races. Hopefully, I just need to put everything back together again and it should work. I've heard that the bearings for the 9x20 are pretty easy to find. Since I have the head stock apart, should I order some and swap them out? Again the originals look good and move freely within.

Before I do put it back together, I want to check the roundness of the spindle where the bearings make contact. I've seen a procedure for that using v-blocks and a DTI, but they also used a precision surface. I don't have one, is that going to be significant problem with the testing? I can't afford the cost and the shipping on the size surface I really want. It will have to wait a bit.

At first glance it looks like I may have a problem removing the chuck side bearing. It did not want to come off. Any suggestions on how to take it off gently? I could do the spindle puller trick in reverse against the spindle and hopefully use a piece of PVC pipe that is close to the same diameter as the bearing washers.

Last edited:

- Joined

- Oct 13, 2012

- Messages

- 175

Ugh, lots of lessons learned during the spindle swap out. I'm not even sure I want to detail my mistakes, but I got the spindle swapped out from the HF 9x20. I then ran the lathe with just the three jaw chuck attached for 20 minutes to break in the bearings in. My thermal tester showed that the spindle temperature rose only six degrees over the 20 minute run. The "wha...wha...wha..." sound while turning is gone, and the lathe same sounds much happier. When I measured the play in the spindle my DTI showed less than half a thousand along the axis and only one thousand perpendicular to the spindle axis. I get a nice one and half to two revolutions on the spindle when I give it a quick spin by hand, so the preload looks good.

I'm still getting a rough cut, but much better than before. I expect it's either spindle speed or the cheap Lowes bar stock I'm using. There seems to be little pits on both the facing and turning cuts.

I'm still getting a rough cut, but much better than before. I expect it's either spindle speed or the cheap Lowes bar stock I'm using. There seems to be little pits on both the facing and turning cuts.

- Joined

- Dec 1, 2010

- Messages

- 1,172

A few things you might consider, If you only got a 6 degree rise in 20 min run time, that isn't much. You could most likely stand for a bit more bearing preload. Another question is what type of cutting tools are you using? If your using carbide insert type, try turning up the spindle speed, other wise use HSS, and make sure you tool is on cenre of coarse. You might want to go over the gib adjustment too, make sure everything is snugged up. The finish on your test cuts looks pretty rough, almost as your spindle speed is to low, and the feed is to fast. But, I would check all these things first.