- Joined

- Jul 2, 2014

- Messages

- 7,594

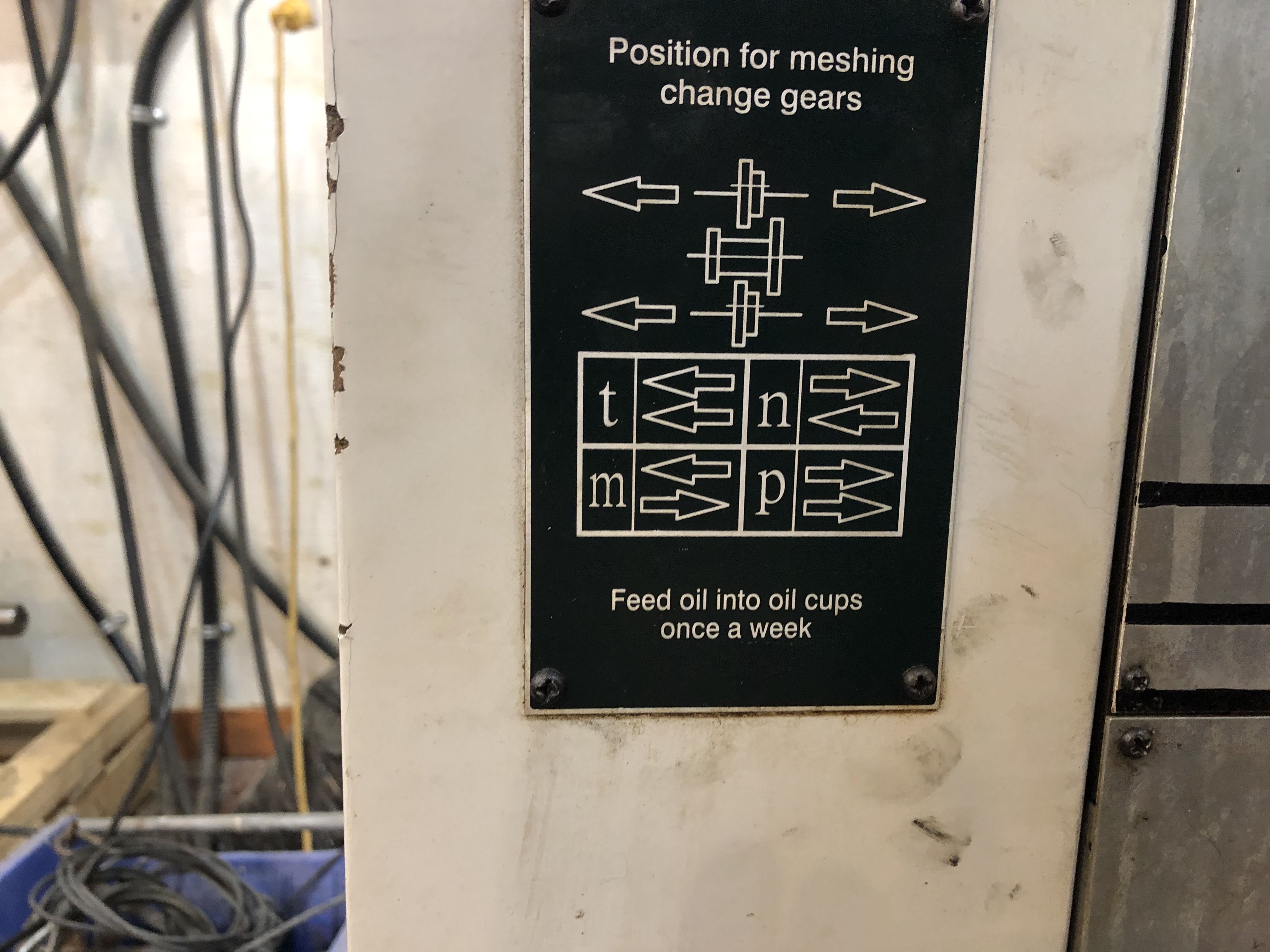

First, make sure you have the change gears for doing 11.5 TPI threads. My lathe requires a different change gear for doing 5 3/4, 11 1/2, 23, and 46 TPI.

Most american lathes have 11 1/2 on the chart, since it is our common thread for pipe, British lathes would tend to have 19 TPI since that is what they use for 1/4" pipe, they use 28 for 1/8" pipe, lathes made in Asia would have similar differences relating to their standards, deleting some that we use and substituting those that they use, regardless of the fact that they are exporting them to our or other market with different standards.First, make sure you have the change gears for doing 11.5 TPI threads. My lathe requires a different change gear for doing 5 3/4, 11 1/2, 23, and 46 TPI.