Like most things, you're mileage may vary, and my advice might be unsuitable. I don't have any advice for your specific machine, but I've pulled apart a few machine tools, and thought I'd share my experience with spindles.

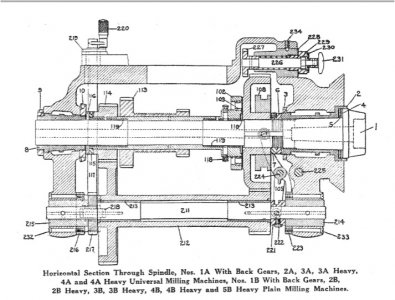

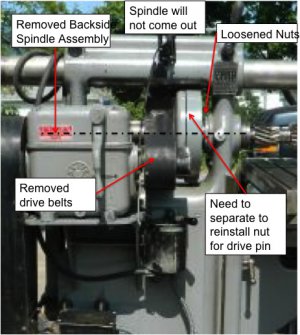

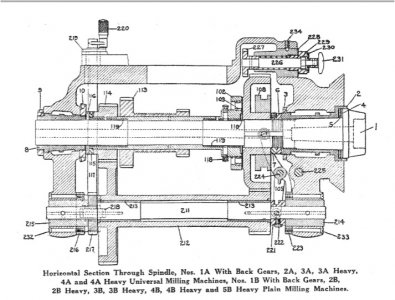

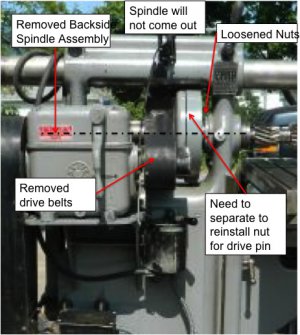

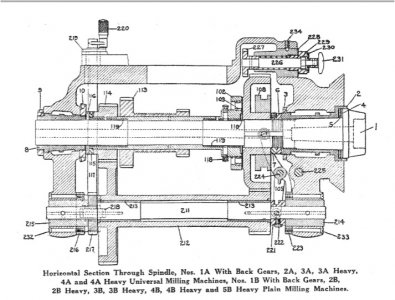

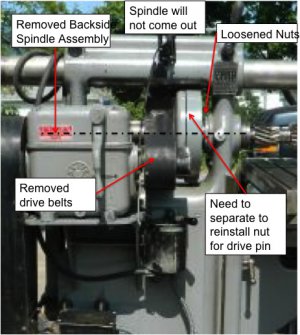

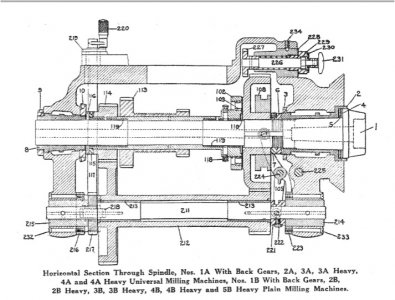

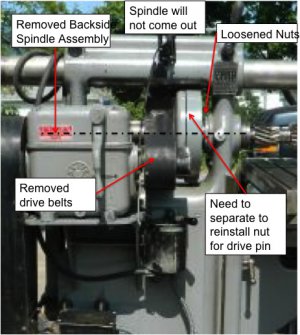

I have a 100 year old horizontal mill that I had trouble getting the spindle out of. It had a large keyed back gear on it, it took a really good clonk with a 4lb soft brass hammer to get that key un-stuck. Once past a burr on the key, it came off with little taps with a smaller brass hammer. I worked up carefully from small gentle taps to larger ones until it moved. It was very easy to see that I had no other retaining nuts or anything in place though, very simple open machine. Don't forget to protect the threads with a loose nut if you're hitting near any. YMMV though, because this mill had huge bronze bearings less likely to be damaged by a large impact and the only thing in the way was this gear and a pulley, no bearing races. I can't tell for sure from the digram if it's a bronze bearing or ball/roller, but I think it's a similar thing to mine, bronze tapered bearings, so should be relatively safe to work up to increasingly bigger taps from the left end ONLY IF it looks like nothing fragile will be damaged by being forced into anything at the front. Also, the thing that you think is jamming it up might not be. I thought it was a pulley, it turned out to be the back gear.

My vertical attachment spindle has some pretty big modern roller bearings. If heated up to about 250f, they'd slide right on if you got it started straight. I never could apply heat that would remove them once installed with hand pressure though. Once at a temp where I started to get concerned, things still never moved. Always had to press or tap (with surprising force) that spindle out if the bearings were already installed. The thing doesn't seem worse for wear from doing that.

Even on my 3 year old lathe, the tolerances in there are close enough that it's not just going to slide out. I would describe it as a very light press fit. Fingers won't get it out, but a light tap with a hammer made progress. Totally different machine than yours, but the point is, every machine I've pulled the spindle out of has never slid out nicely. It's always been a bit of a fight.

If you're sure you've got all of the retaining mechanisms off (lock nuts, whatever), tap, jiggle, vibrate, make sure stuff isn't cocked and bound, and try tapping things that are stuck on opposite sides back the way they came to see if they were stuck cocked. Keep turning the spindle as you tap so you're not always tapping on one side of a part.

It's a tough thing to evaluate over the internet. It may be that you've still got something attached, or there's a trick, I don't know. Always seemed like a bit of a black art learned through struggle. Let us know how you make out!