- Joined

- Oct 17, 2018

- Messages

- 922

I have an Atlas Craftsman lathe that came with a motor that was wired for reverse and forward by the PO. The wires were rotten, cracked and filthy, so they need to be replaced and the machine needs to be wired to go forward of off, as on the original. This is what I have:

#1. HOW TO CONNECT CLOTH COVERED WIRES TO PLASTIC ONES

There are two wires coming from the motor. I can't tell where. These are connected to the original power cord. How do I attach these to a new cord wire? They are cloth-covered, so I want to know if there's anything special that needs to be done when connecting them. I thought I would use butt slices or wire nuts.

The black wire is the hot one, the white is neutral, but what about a ground wire?

The silver stud on the left is connected to a plate and the one on the right has a wire coming from inside the motor and is also connected to the same plate at a different point.

#2. CORRECT WIRING

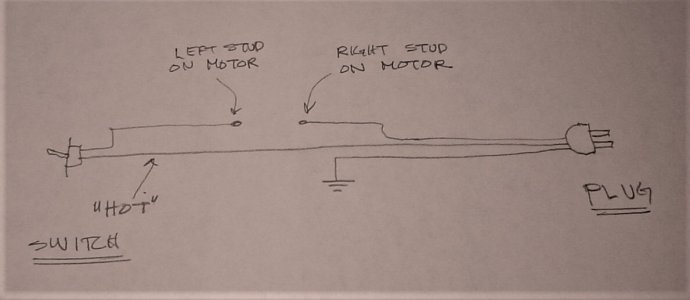

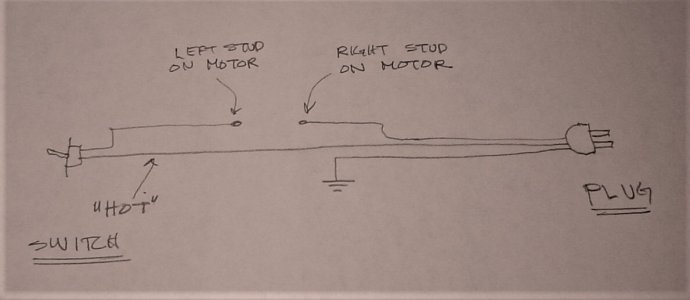

My plan was to connect the wires as shown, but I don't know how a ground needs to be connected:

Electricity is not my strong suit, so I thought I'd ask and see the correct way to do this. Thanks!

#1. HOW TO CONNECT CLOTH COVERED WIRES TO PLASTIC ONES

There are two wires coming from the motor. I can't tell where. These are connected to the original power cord. How do I attach these to a new cord wire? They are cloth-covered, so I want to know if there's anything special that needs to be done when connecting them. I thought I would use butt slices or wire nuts.

The black wire is the hot one, the white is neutral, but what about a ground wire?

The silver stud on the left is connected to a plate and the one on the right has a wire coming from inside the motor and is also connected to the same plate at a different point.

#2. CORRECT WIRING

My plan was to connect the wires as shown, but I don't know how a ground needs to be connected:

Electricity is not my strong suit, so I thought I'd ask and see the correct way to do this. Thanks!