- Joined

- Dec 26, 2015

- Messages

- 2,079

Using my new PM935, and coming from a Rong Fu 45 (the real one, not a clone), it seemed to me that every time I reached for the single quill feed handle, it was indexed to the wrong position. So I decided to make a new 3-spoke handle out of stainless.

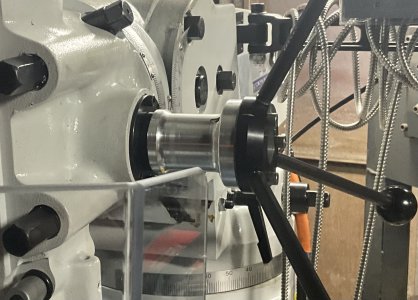

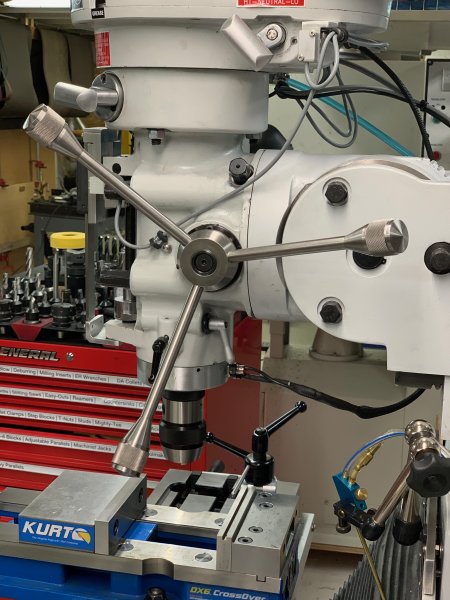

The quill feed handle interface to the mill head looks like this.

And the factory supplied handle is like this.

So the first step was to make the hub element that fit onto the quill feed spindle.

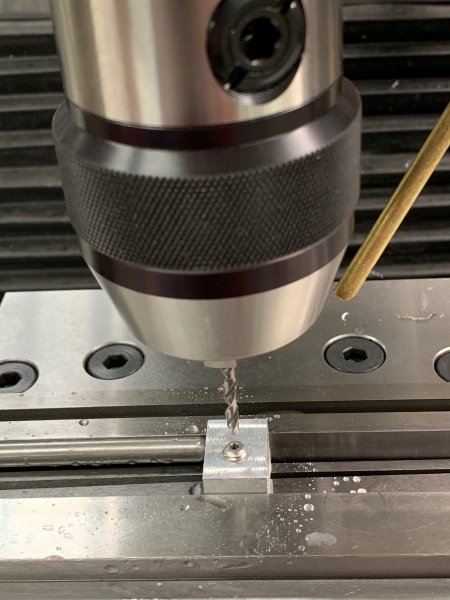

Ready to drill out for the quill feed shaft and the three spokes for the handles.

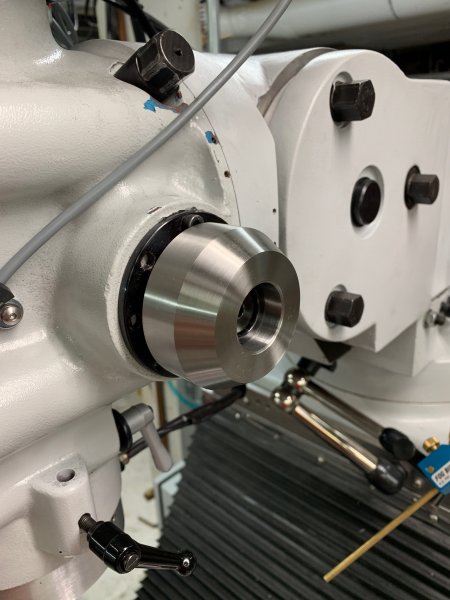

After drilling out and boring for the quill feed shaft, a test fit on the mill.

That hub was over-thick, but I decided to move on with the spoke handle part of this. I tilted the mill head 60-degrees, and used the rotary table with 3-jaw chuck to hold the hub, and drilled and tapped for M10 spokes.

After machine tapping as deep as possible, I finished by bottom tapping by hand.

The spoke making was easy - 1/2" 304 round bar, threaded M10 at the end. Test fit to access the required length.

Next step was to turn the knobs for the end of the spokes. And the first step in that process was knurling the 1.5" diameter 304 round bar. Here's how that went.

After some additional lathe work, I had my three knobs, threaded M10 for the spokes.

The hub was machined down in thickness and drilled and tapped for set screws to hold it on the quill feed shaft and for a pin to index into the feed shaft indexing holes. Checking my hardware stock, I realized I did not have any brass-tipped set screws in suitable size, so I made my own from stainless M6 set screws.

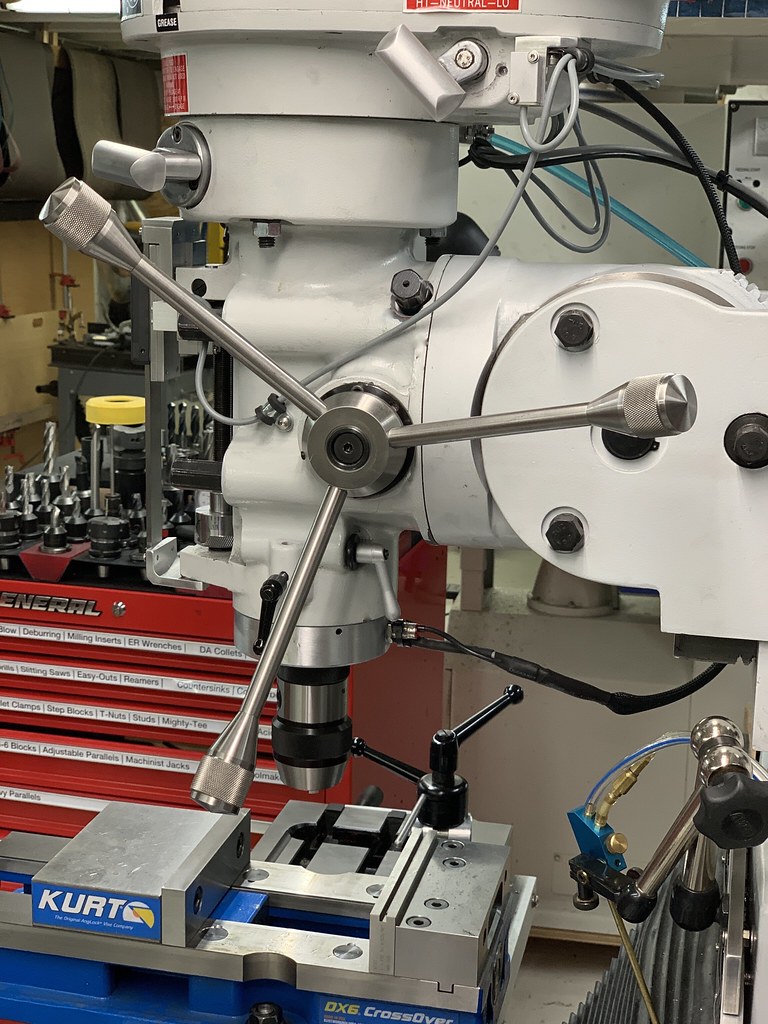

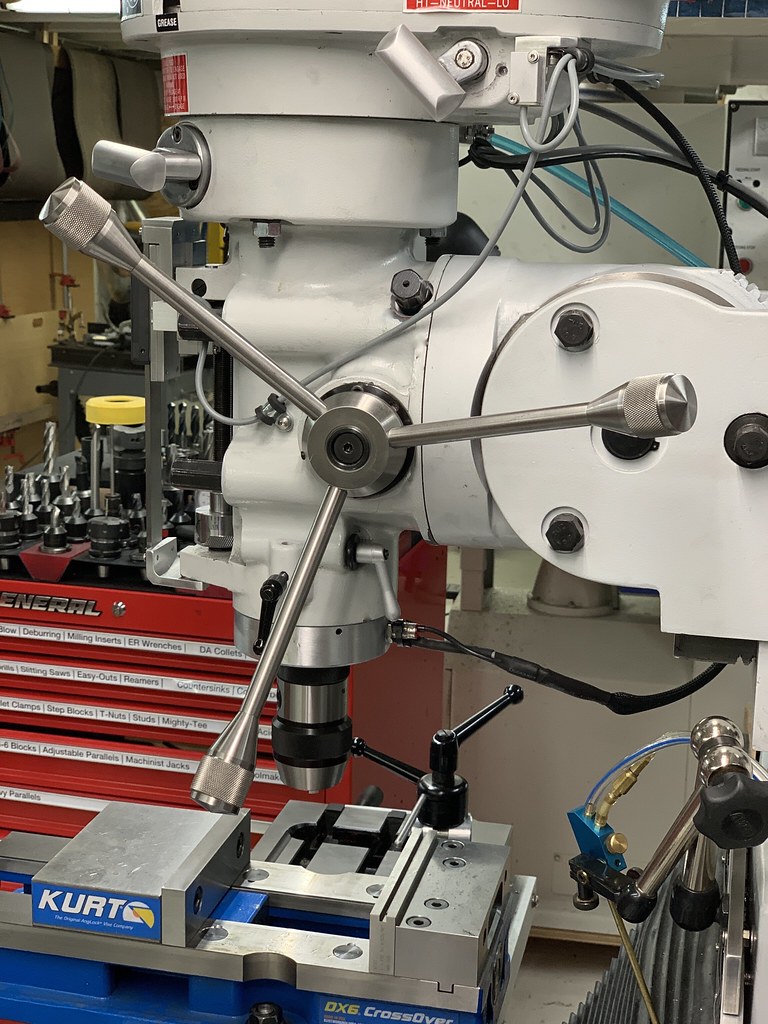

And the final result.

It works well, and a knob to grab is now always within reach. I may still shorten the spokes another 1.5 inches or so - still getting used to it.

This was a fun project. The complete build log is here if anyone is interested:

The quill feed handle interface to the mill head looks like this.

And the factory supplied handle is like this.

So the first step was to make the hub element that fit onto the quill feed spindle.

Ready to drill out for the quill feed shaft and the three spokes for the handles.

After drilling out and boring for the quill feed shaft, a test fit on the mill.

That hub was over-thick, but I decided to move on with the spoke handle part of this. I tilted the mill head 60-degrees, and used the rotary table with 3-jaw chuck to hold the hub, and drilled and tapped for M10 spokes.

After machine tapping as deep as possible, I finished by bottom tapping by hand.

The spoke making was easy - 1/2" 304 round bar, threaded M10 at the end. Test fit to access the required length.

Next step was to turn the knobs for the end of the spokes. And the first step in that process was knurling the 1.5" diameter 304 round bar. Here's how that went.

After some additional lathe work, I had my three knobs, threaded M10 for the spokes.

The hub was machined down in thickness and drilled and tapped for set screws to hold it on the quill feed shaft and for a pin to index into the feed shaft indexing holes. Checking my hardware stock, I realized I did not have any brass-tipped set screws in suitable size, so I made my own from stainless M6 set screws.

And the final result.

It works well, and a knob to grab is now always within reach. I may still shorten the spokes another 1.5 inches or so - still getting used to it.

This was a fun project. The complete build log is here if anyone is interested: