- Joined

- Jul 11, 2014

- Messages

- 496

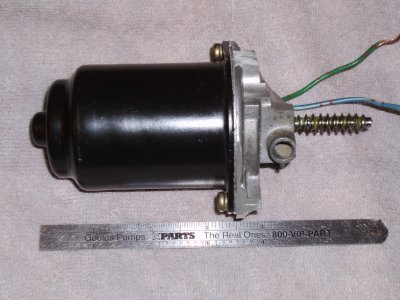

Bought this wiper motor on Ebay, good price and fast delivery, can't beat that. Still haven't checked to see if it runs but have taken their word on faith and have started to work with it.

I intend to make a quill drive (X axis) for the mill. Not much of a project yet but it's a start. (I meant Z axis, I can't tell my X from my Y/Z sometimes)

I just milled some of the un-necessaries from the top. Wanted to see if I could use the existing top or if I should machine another. I'm leaning toward machining a new plate for the top and incorporating it into the mount, whatever that ends up looking like, to attach the motor to the quill fine feed. Lot of questions and thoughts right now about how not as many answers but they'll come in time.

I talked to the 'Old Guy' (me calling him old???) about the wiring, he used to be an electrician. Well I guess he still is an electrician just a retired one. He told me what to try to wire the motor to a power supply. Made some other suggestions too. I think he's interested and wants to get involved. He saw the inside of my shop/shed the other day and has been kinda watching when I go in there. Hey, he's welcome anytime I'm there.

My next decision is how to mount the motor, that is, in parallel with the fine feed shaft or perpendicular. Depends on how I want to 'drive' the fine feed. With a belt, a chain or gearing.

I intend to make a quill drive (X axis) for the mill. Not much of a project yet but it's a start. (I meant Z axis, I can't tell my X from my Y/Z sometimes)

I just milled some of the un-necessaries from the top. Wanted to see if I could use the existing top or if I should machine another. I'm leaning toward machining a new plate for the top and incorporating it into the mount, whatever that ends up looking like, to attach the motor to the quill fine feed. Lot of questions and thoughts right now about how not as many answers but they'll come in time.

I talked to the 'Old Guy' (me calling him old???) about the wiring, he used to be an electrician. Well I guess he still is an electrician just a retired one. He told me what to try to wire the motor to a power supply. Made some other suggestions too. I think he's interested and wants to get involved. He saw the inside of my shop/shed the other day and has been kinda watching when I go in there. Hey, he's welcome anytime I'm there.

My next decision is how to mount the motor, that is, in parallel with the fine feed shaft or perpendicular. Depends on how I want to 'drive' the fine feed. With a belt, a chain or gearing.

Last edited: