- Joined

- Oct 18, 2016

- Messages

- 2,872

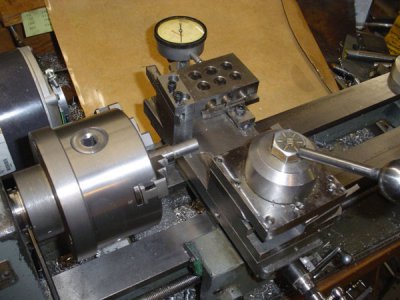

Just finished making up a post that will in some setups replace the compound on my Logan. Why would I bother, you might ask? I've been wanting to switch from 3/8" to 1/2" tools, and with my AXA toolholder all the way down the tip of the tools are higher than spindle centerline. I also bought a Dorian cutoff holder

that has the same problem. After thinking about various ways to solve this problem I decided to make this part. I figured it would also give me some extra

rigidity for parting off, interrupted cuts or just to allow greater DOC when roughing out.

The post was turned from a lump of 1144. The stud is 1144 as well and the nut was made from 12L14 1" hex bar. The parts were blued and oil finished.

After taking some test cuts, I think this setup is more rigid than with the compound in place. I took deeper cuts than before without protest from the

lathe, and the surface finish looked a bit better doing it, so I think this project is a success. Now I can start to accumulate some 1/2" tools, which should

give me a bit more rigidity as well. This baby lathe needs all the help it can get and unless I need the compound this will probably become

my default setup.

that has the same problem. After thinking about various ways to solve this problem I decided to make this part. I figured it would also give me some extra

rigidity for parting off, interrupted cuts or just to allow greater DOC when roughing out.

The post was turned from a lump of 1144. The stud is 1144 as well and the nut was made from 12L14 1" hex bar. The parts were blued and oil finished.

After taking some test cuts, I think this setup is more rigid than with the compound in place. I took deeper cuts than before without protest from the

lathe, and the surface finish looked a bit better doing it, so I think this project is a success. Now I can start to accumulate some 1/2" tools, which should

give me a bit more rigidity as well. This baby lathe needs all the help it can get and unless I need the compound this will probably become

my default setup.

Last edited: