Now that I have your attention. (Sorry about that click bait

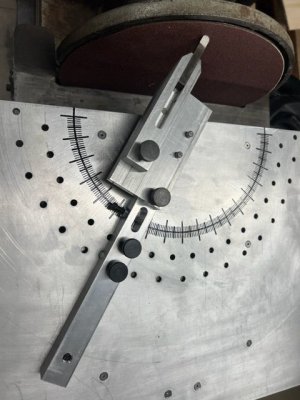

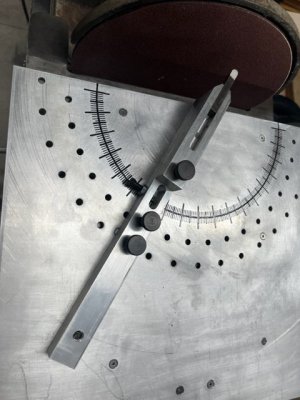

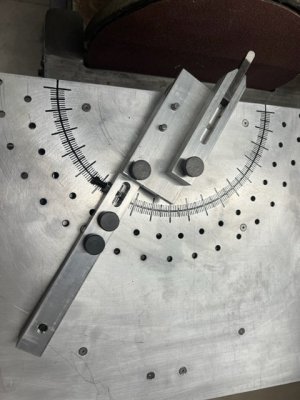

) I was thinking about ways to grind lathe tool bits etc a bit more accurately than by hand so attached a piece of shaft to the base of my spindex and clamped it in the mill vise. Works fairly well to set the spindex at a vertical angle by rotating and clamping the shaft in the vise. Then a compound angle can be achieved by indexing the spindex.

) I was thinking about ways to grind lathe tool bits etc a bit more accurately than by hand so attached a piece of shaft to the base of my spindex and clamped it in the mill vise. Works fairly well to set the spindex at a vertical angle by rotating and clamping the shaft in the vise. Then a compound angle can be achieved by indexing the spindex.

Could even achieve a third angle using a vise with the compound under it.

Got to thinking that a fella (or fellette) could combine a pair of spindexers to do the same thing. So continuing my pursuit of Fusion 360 learning practice, decided to model one. Everyone should own two spindexers, right?

Could even achieve a third angle using a vise with the compound under it.

Got to thinking that a fella (or fellette) could combine a pair of spindexers to do the same thing. So continuing my pursuit of Fusion 360 learning practice, decided to model one. Everyone should own two spindexers, right?