- Joined

- Oct 14, 2014

- Messages

- 1,970

I am building a spider to go inside my lathe spindle bore. It needs to feed coolant to the part that is being deep hole drilled. Need to seal the coolant to not spray out the back of the part.

the only given here is the bore on the part - 10mm.

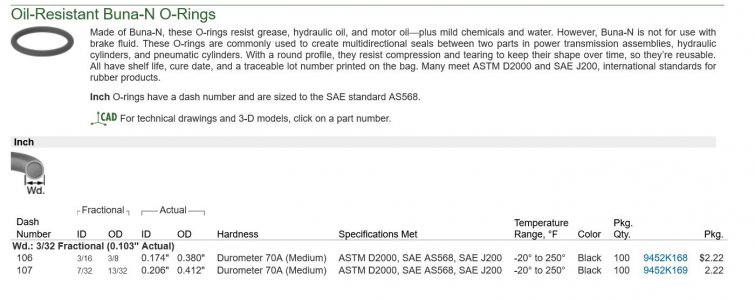

I want to fit a metal tube inside this bore with an O ring to seal it. Started reading machinery handbook and just got hopelessly confused. looks like I need to solve for D, G, and B/2 for an OD sealing O ring. AND then pick out which O ring to purchase.

See page 2602 from my handbook below.

the only given here is the bore on the part - 10mm.

I want to fit a metal tube inside this bore with an O ring to seal it. Started reading machinery handbook and just got hopelessly confused. looks like I need to solve for D, G, and B/2 for an OD sealing O ring. AND then pick out which O ring to purchase.

See page 2602 from my handbook below.