- Joined

- Aug 3, 2022

- Messages

- 5

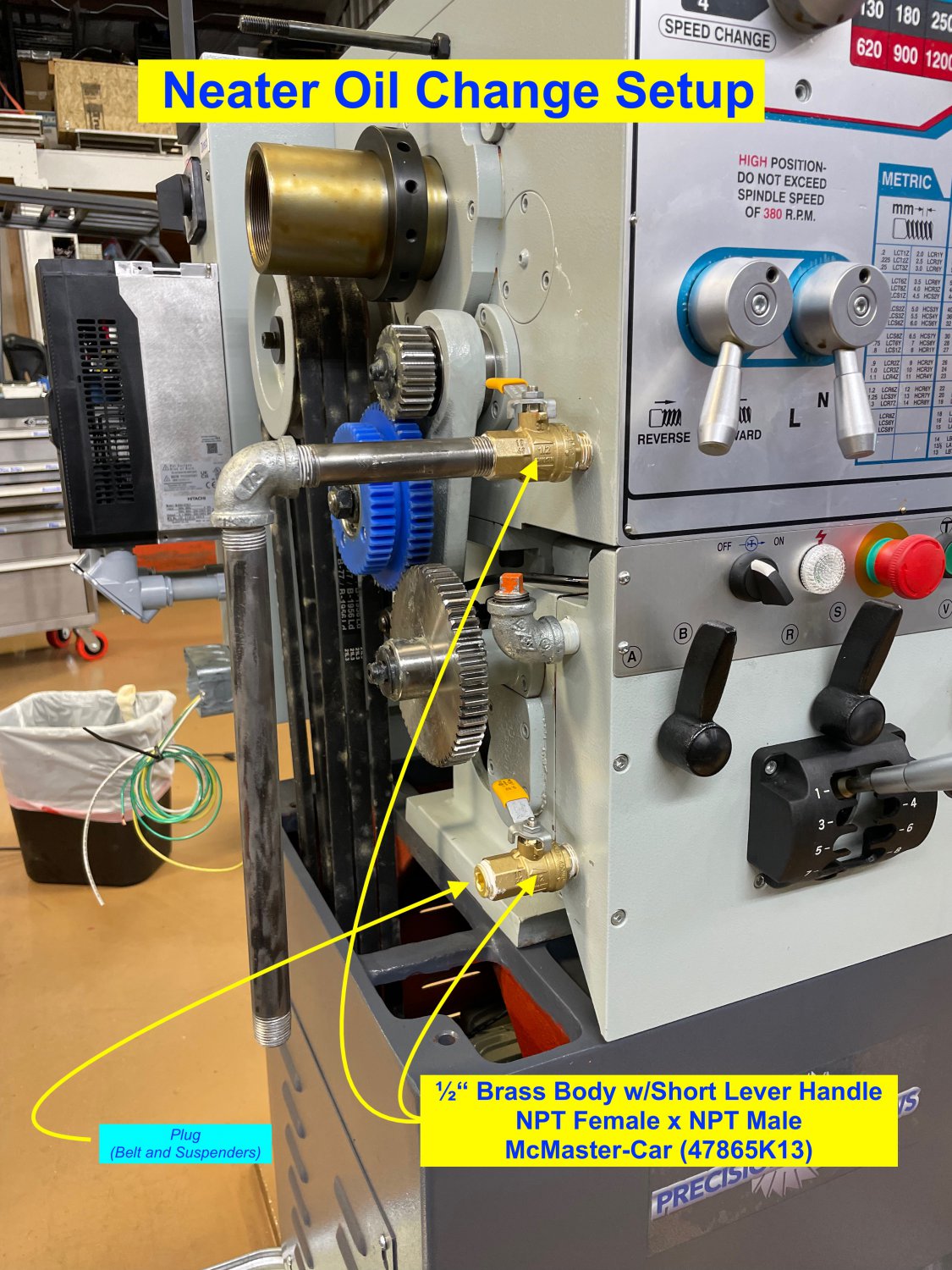

I thought I would share an idea that I have used with other lathes to make the oil change a little easier and cleaner.

Good idea... thanks for the additional information.Fulmoto valves are another solution, very compact and you can not accidentally opent them. If you get one of the S series valves it has a short special nipple.

The sell a little 2 dollar accessory that goes in the end of some 3/8 clear tubing and snaps over the short nipple. Put it down into an empty oil jug and open the valve, wont spill a drop.

I have them on all my cars, mowers, tractor, and put them on a lot of the machine tools at work. Every one loves them.

I have had the same experience with a previous lathe. I have started putting a 5 gal. bucket under by drain set up and leaving it for the the night (headstock in particular).I should note you won't spill a drop if you use your head.

At work I take three empty 2 gallon jugs out to three machines, lock them out, and start draining oil into them.

I let them drip empty if I have scheduled time and the hose is clear.

Well one other guy would take one jug, open it and talk to a nearby operator.

Move to another machine withe the 3/4 full jug, open the valve, and invariably talk again to someone and forget, spilling a gallon of oil over the floor. It happened again, and again.