-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Owners of Maximat 7

- Thread starter Buddy Bronze

- Start date

- Joined

- Dec 20, 2012

- Messages

- 9,422

Just a heads up for you Maximat 7 guys. There is a cross slide lead screw and nut on ebay right now: https://www.ebay.com/itm/Emco-Maxim...491758?hash=item3d544f5aae:g:BbQAAOSwSdZaRDJU

Emco lathes have good longevity but like any lathe, the most wear occurs in the cross slide lead screw and nut. As these are no longer available, it might be good idea to grab it.

Emco lathes have good longevity but like any lathe, the most wear occurs in the cross slide lead screw and nut. As these are no longer available, it might be good idea to grab it.

I am having this same problem. Has any one come up with a solution?

I can not visualize how the "clutch" can be engaged with the selector without also engaging with the shaft that mounts into the banjo. If the gear is powered, the entire assembly spins and unthreads from the banjo. I am sure it is a simple solution that I ma not visualizing.

I can not visualize how the "clutch" can be engaged with the selector without also engaging with the shaft that mounts into the banjo. If the gear is powered, the entire assembly spins and unthreads from the banjo. I am sure it is a simple solution that I ma not visualizing.

The center is flip flopping between the two larger gears, but staying engaged with the next gear down.I am having this same problem. Has any one come up with a solution?

I can not visualize how the "clutch" can be engaged with the selector without also engaging with the shaft that mounts into the banjo. If the gear is powered, the entire assembly spins and unthreads from the banjo. I am sure it is a simple solution that I ma not visualizing.

My speed selector knob is also locked up solid. Did you guys figure it out? I noticed that the videos online, they always have the machine on when selecting the speed. Is that required?

I'm in the midst of bringing a Maximat 7 back to life.. I don't have it plugged in yet.. I dont even know if its single of 3 phase.. There are 4 wires on the plug, so I assume 3.. Motors say 220v.. anyway, thats a tangent!

Is there a replacement Maximat 7 group online now?

Is a manual available online? Some guy on ebay is gouging folks for them..

Re your PM

Look at the first picture on this post. You can see he replaced the pin with a copper one. It is too long and will not let the selector slide freely laterally. That is the problem I was having

Also, my Maximat is single phase and was originally purchased as such (I am in the US).

Look at the first picture on this post. You can see he replaced the pin with a copper one. It is too long and will not let the selector slide freely laterally. That is the problem I was having

Also, my Maximat is single phase and was originally purchased as such (I am in the US).

- Joined

- Jun 3, 2023

- Messages

- 1

The pin isnt supposed to extend through the holes in the "slider." (Odd shaped part the center gear is keyed to) The holes are there so the pin can be installed/removed. The pin ends ride against the walls of the inside of the "slider" and said "slider" can rotate freely relatve to the actuator pin shaft. I fought with mine for days, but finally got it. HTH.

- Joined

- Jul 13, 2017

- Messages

- 638

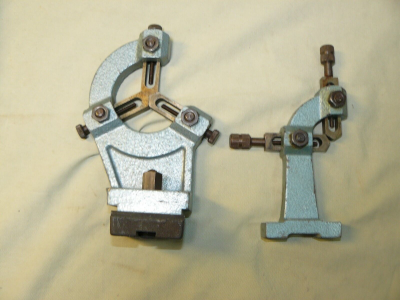

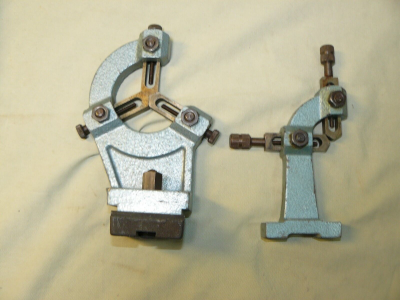

Not mine but here are steady and follow rests for a Maximat 7 at a reasonable opening bid:

Emco Maximat 7 Steady Rest and Follower Rest | eBay

Find many great new & used options and get the best deals for Emco Maximat 7 Steady Rest and Follower Rest at the best online prices at eBay! Free shipping for many products!

www.ebay.com