Those pistons, especially the LHS one look to be more like 1960s than 1930/40s. You say horizontal engines, that will be Aermacchi or Motobi. When I first saw your pistons and before I read your post my reaction was "those look like 250 Aermacchi pistons". What is the piston diameter, that will say a lot? Here is a pic of a 1973 350 Aermacchi piston, unfortunately the camera angle has hidden the crown mostly. The 350s had a small swish band which yours do not. I will take a photo of a 250 piston and measure the rings and return with an update.

Hi Tony - thanks for the reply, and the picture.

You are very likey correct in thinking those two beat up old pistons are probably more modern than 1940s, if only because the oiling ring is no longer at the bottom of the skirt. See the pictures of the strip-down pistons in the

"Pistons problemo" thread.

The original was 60.8mm (ie. 2.394" or 2+25/64"). The stroke was 60mm. The compression ration only 6 to 1. Despite the 350cc, they were low powered. Later engines used 8 to 1 ratio, and got up to around 28bhp. Most bikes used two Amal carburetters, on each cylinder.

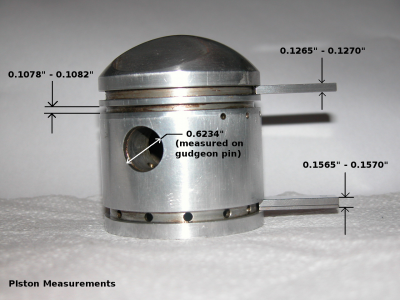

Yes - I guess some Douglas owners, desperate for rare parts, might well put anything they can find or contrive with the right bore, and uses a 5/8" wrist pin. No way would the pistons you see have gone into the same engine. It would have shaken the bones out! As I understand it, the pistons have to be exactly the same shapes & rings, and weigh the same. Moreover, that weight had better be the correct weight to match the counterweights on the crankshaft. All these beat up pistons might contribute is their basic shape casting with the dome crown, and being +0.030"m might clean up (down??) with a 0.005" cut, with taper and skirt ovality preserved. Also, rings depth fixed. Also, new rings as per the original

I have little to lose in attempting some possibly extreme measures here. One approach might be to TIG weld up the ring slots with 4032 alloy and then re-create the originals. That would be 3 rings slots. Top is two standard compression rings. Next is a stepped ring. Then, third is down on the skirt oil control ring.

Another, possibly bizarre and desperate idea is to rework the originals (like the one in the picture), by using conventional electro-less nickel strike as precursor to a layer of (say) copper, to build up the thickness by most of the 0.010", followed by a final layer of some suitable metal to run in a iron-nickel alloy bore. Yes - I do understand I am going where maybe I should not, and that I don't know enough, and that there are zillions of ways to mess up!