- Joined

- Mar 14, 2014

- Messages

- 175

We got about 3" of snow today so I spent the afternoon in the shop.

I needed a way to center my 3 jaw chuck on the rotary table, so I turned a plug to fit in the rotary table and in the chuck back. I picked up the chuck on Ebay for cheap, someone bored out the center hole in the back, Its kinda ugly. I'm going to drill some holes thru and make it front mount if I can. The fit in the chuck was almost press fit and fits snugly in the table.

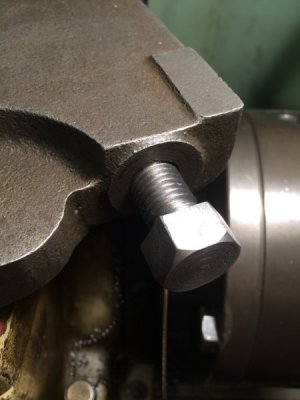

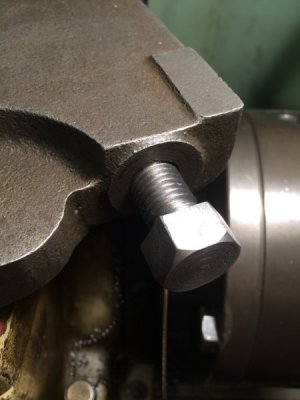

I've been making some parts for a B & S universal vise ( Thanks John ) from some measurements and sketch, found out the threads in a blind hole were not standard. The were 9/16-14, so not having a tap I cut the threads and here's what I ended up with.

Sorry I didn't take any pics milling the hex, I used a hex collet block. I started with 1" round(4140) milled the flat to 3/4"

I needed a way to center my 3 jaw chuck on the rotary table, so I turned a plug to fit in the rotary table and in the chuck back. I picked up the chuck on Ebay for cheap, someone bored out the center hole in the back, Its kinda ugly. I'm going to drill some holes thru and make it front mount if I can. The fit in the chuck was almost press fit and fits snugly in the table.

I've been making some parts for a B & S universal vise ( Thanks John ) from some measurements and sketch, found out the threads in a blind hole were not standard. The were 9/16-14, so not having a tap I cut the threads and here's what I ended up with.

Sorry I didn't take any pics milling the hex, I used a hex collet block. I started with 1" round(4140) milled the flat to 3/4"