- Joined

- Mar 2, 2021

- Messages

- 84

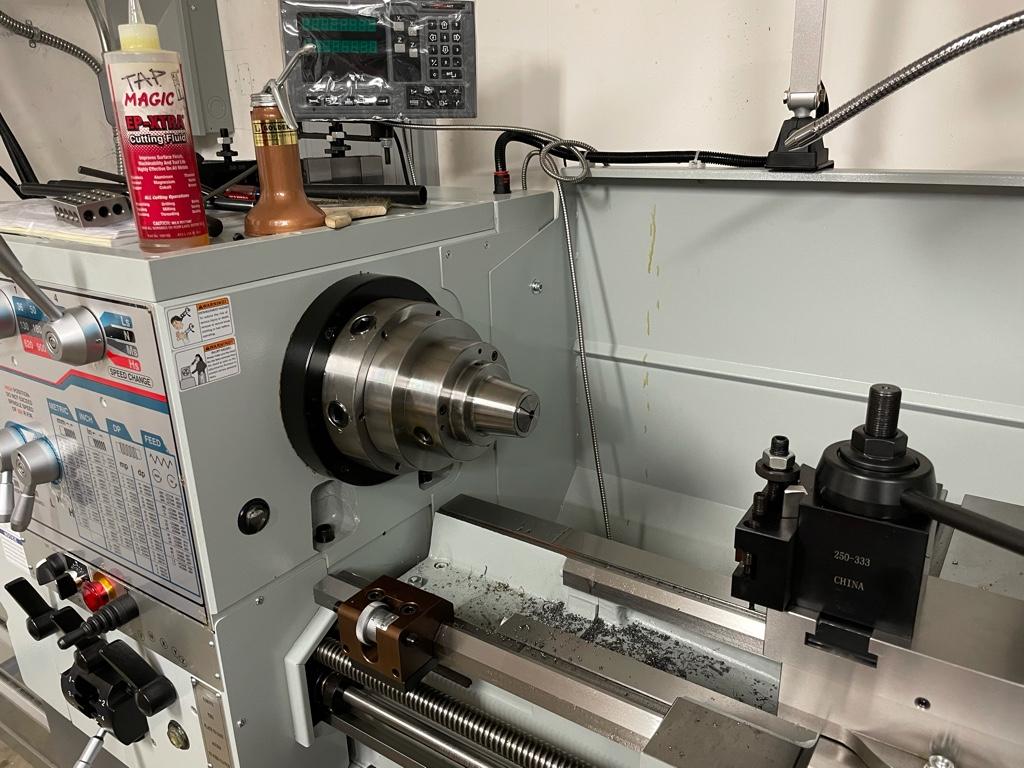

Can’t seem to remove the 3-jaw chuck from my PM-1640.

I built a chuck cradle to hold the chuck, and attempted to use the chuck key to align the cam line to the cam release line, but none of the cam locks seem to want to budge.

I tried using a rubber mallet, but it’s making me nervous that I’m going to mess with the spindle bearings as I’m shaking the whole lathe when I try to use the mallet to hit the chuck key.

Any tips or tricks?

I built a chuck cradle to hold the chuck, and attempted to use the chuck key to align the cam line to the cam release line, but none of the cam locks seem to want to budge.

I tried using a rubber mallet, but it’s making me nervous that I’m going to mess with the spindle bearings as I’m shaking the whole lathe when I try to use the mallet to hit the chuck key.

Any tips or tricks?