- Joined

- Mar 25, 2013

- Messages

- 4,617

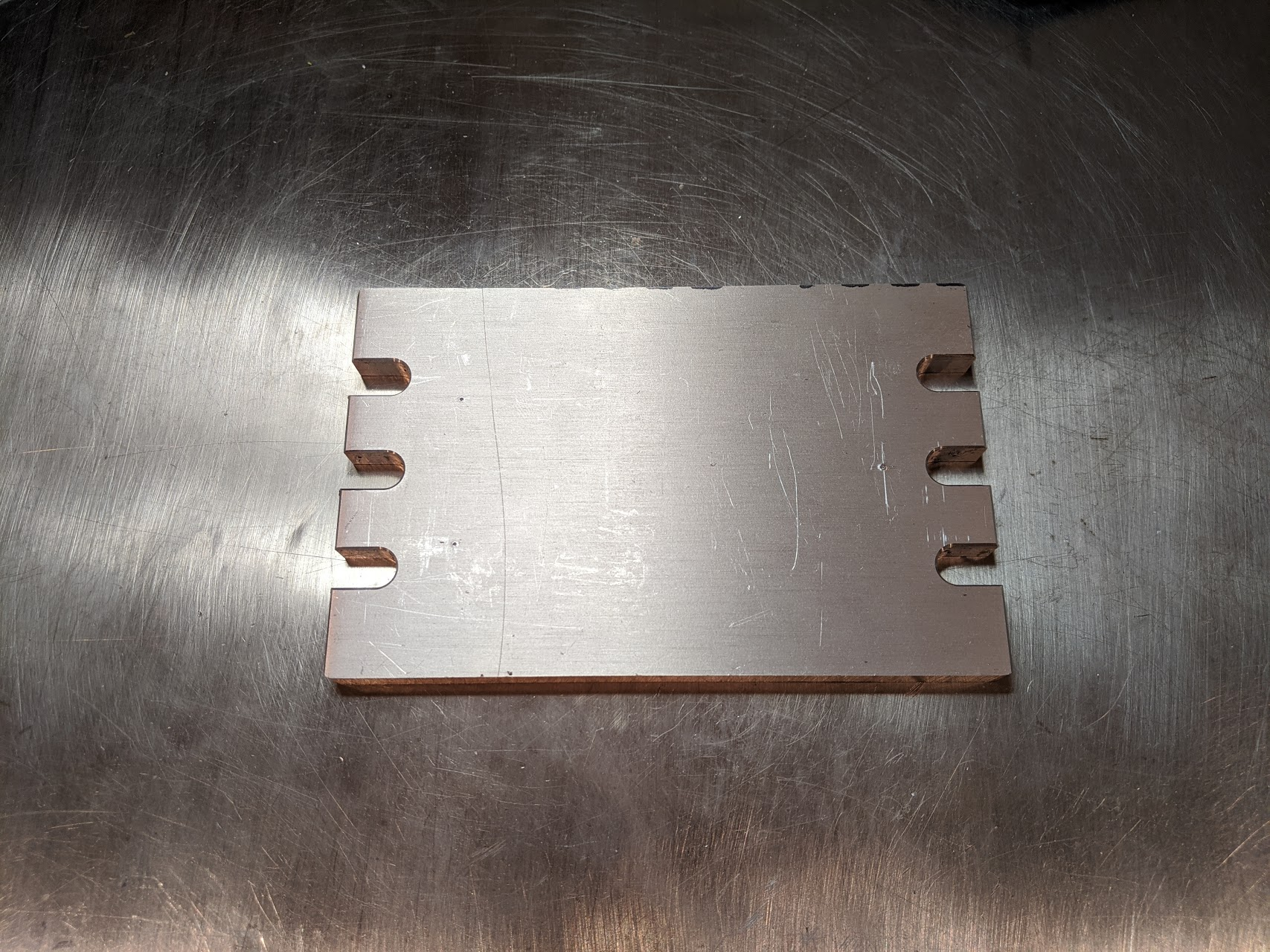

I keep meaning to post this. I made my first cuts in aluminum recently and I was very impressed!

The stock is 3/8" 6061. I used a 2 flute end mill and I did the slots as full thickness passes. The mill handled this easily. I am very pleased with this so far. This plate will be used to mount a small rotary table.

Robert

The stock is 3/8" 6061. I used a 2 flute end mill and I did the slots as full thickness passes. The mill handled this easily. I am very pleased with this so far. This plate will be used to mount a small rotary table.

Robert