-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PM728VT meets 72 David Brown Tractor

- Thread starter RetiredRich

- Start date

- Joined

- Jul 13, 2017

- Messages

- 636

Oil of Olay...

- Joined

- Jul 31, 2020

- Messages

- 765

Here are the pictures I promised. They key things are:

1. The paper instructions which come with the Align Power feed are awful. Go to Precision Matthews website and download the newer (and much better instructions). The paper instructions have you putting the gear on the handle-shaft backwards.

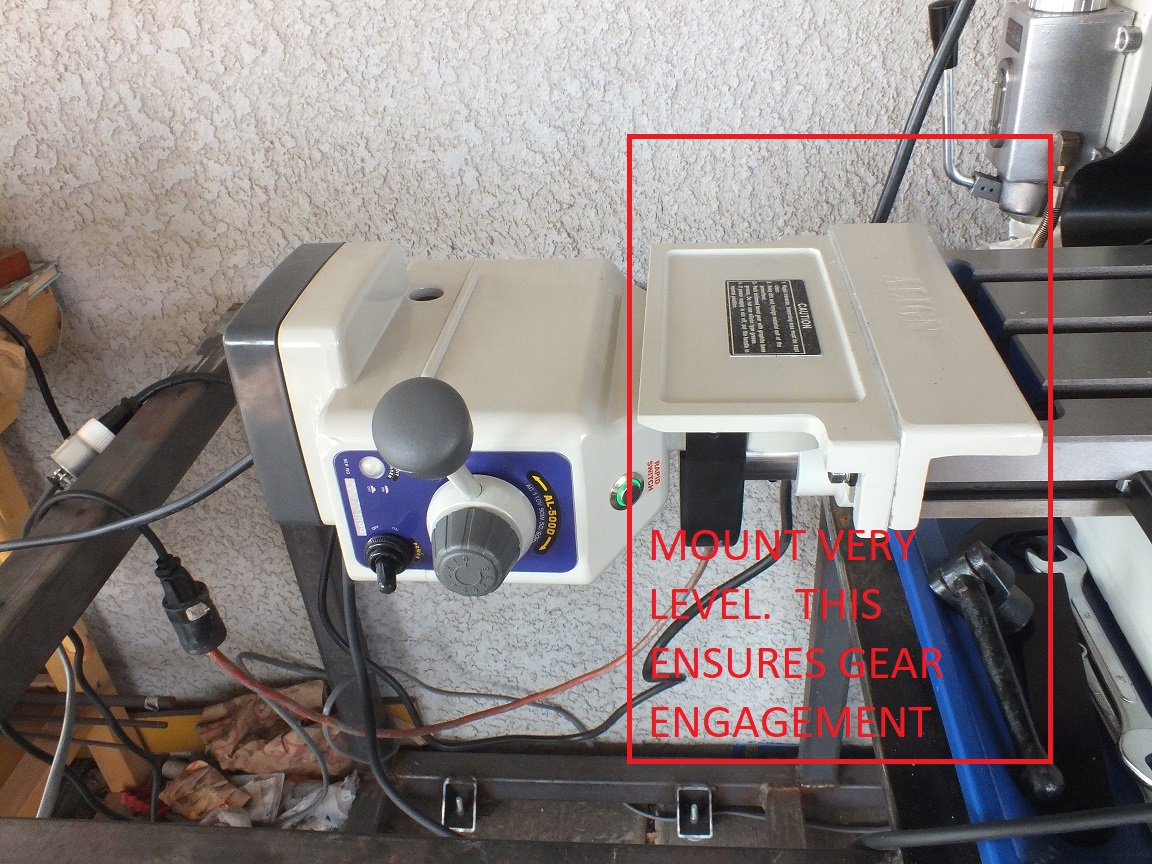

2. Getting the mounting plate LEVEL with the table is vital. Otherwise you will get tilted/pinching gear engagment.

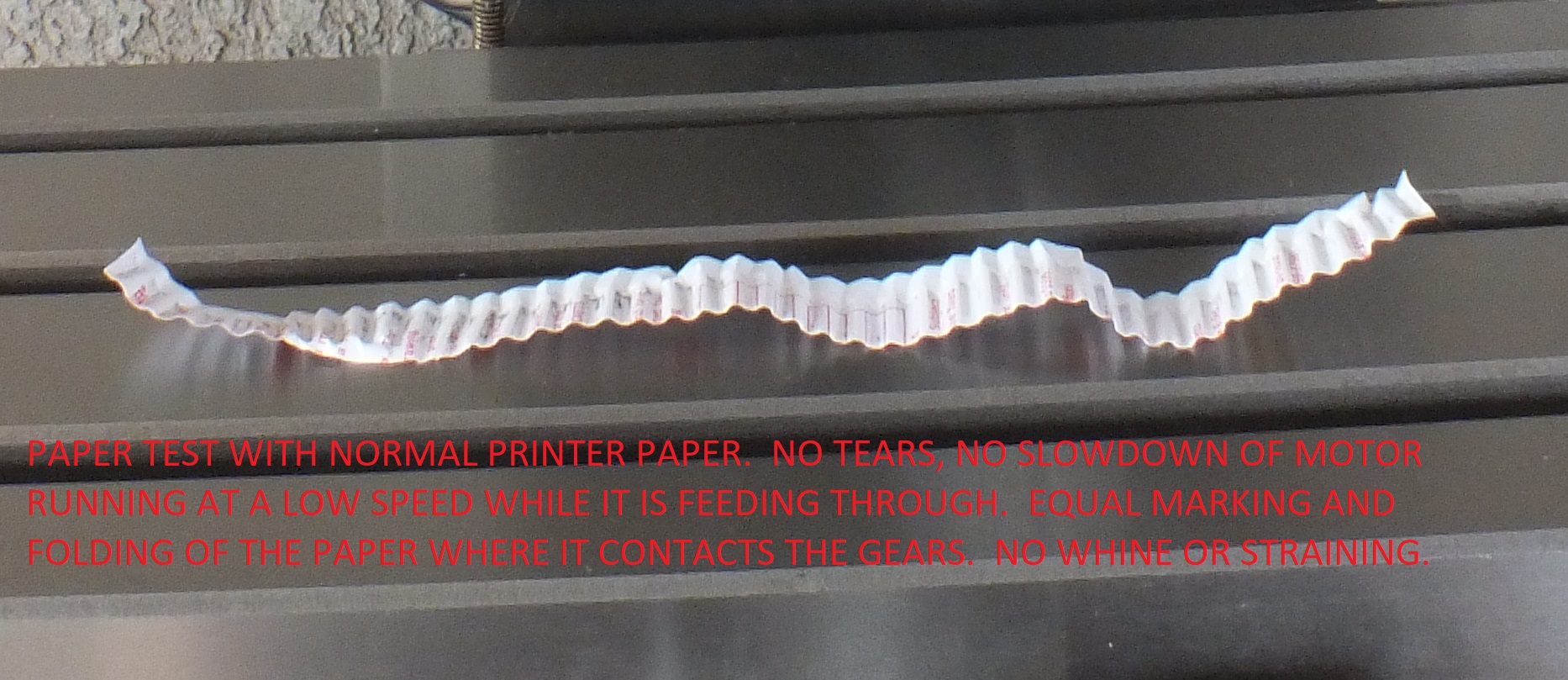

3. Cut a narrow strip of paper to run through the gears to check engagement. It should perfectly fan-fold the paper, without tearing it, but it should leave a clear mark where the teeth squarely engaged with NO Taper. You should do this test with the X-Axis feed moving at a very slow rate. If it is pinching too hard, or tearing the paper, or slowing the motor, then you have the gears meshing TOO Tightly. Use the picture of my test paper as the "gold standard" for engagement. My gear engagement is much lighter then many I have heard, but is still very secure with no "slap/play".

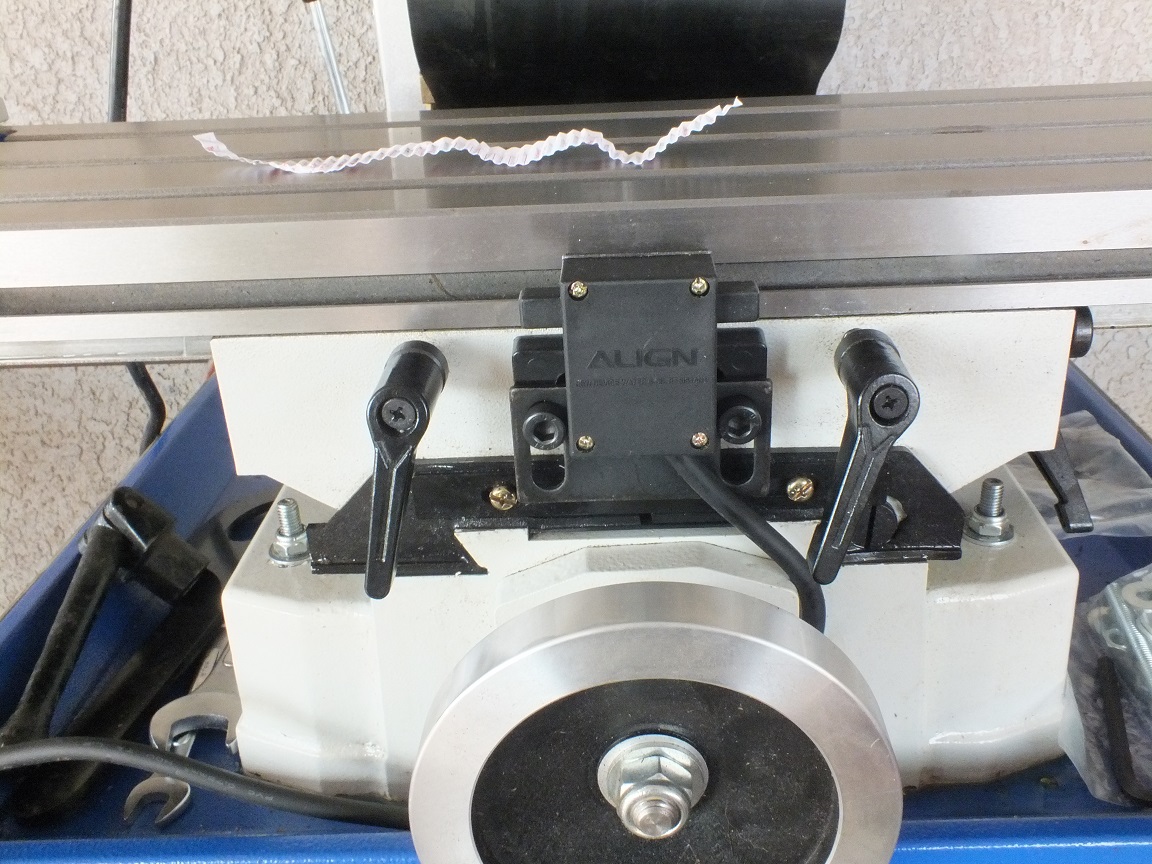

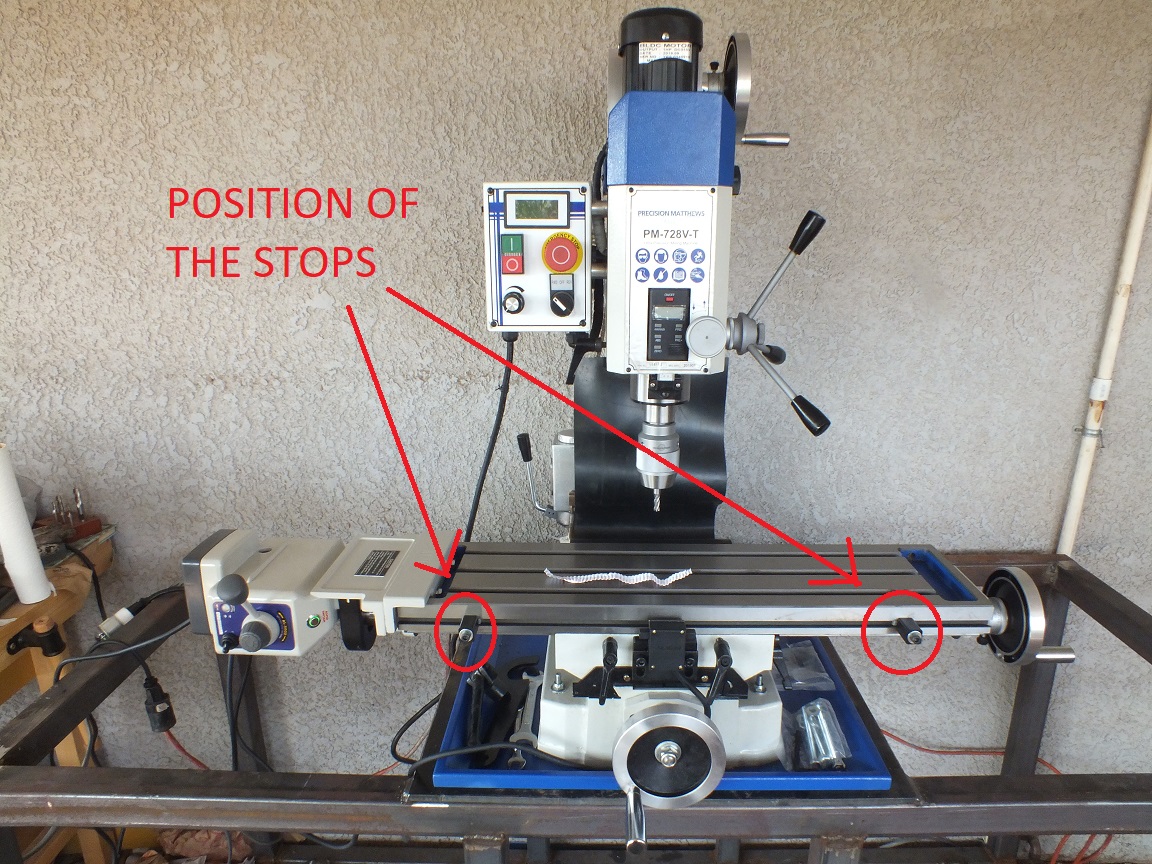

4. I have provided a picture of the install of the limit switch. Do it like this, and all will be well. Just make sure to KNOW where your Stops need to be placed to avoid over-extending the table. This is especially true if you wish to protect your DRO scales.

1. The paper instructions which come with the Align Power feed are awful. Go to Precision Matthews website and download the newer (and much better instructions). The paper instructions have you putting the gear on the handle-shaft backwards.

2. Getting the mounting plate LEVEL with the table is vital. Otherwise you will get tilted/pinching gear engagment.

3. Cut a narrow strip of paper to run through the gears to check engagement. It should perfectly fan-fold the paper, without tearing it, but it should leave a clear mark where the teeth squarely engaged with NO Taper. You should do this test with the X-Axis feed moving at a very slow rate. If it is pinching too hard, or tearing the paper, or slowing the motor, then you have the gears meshing TOO Tightly. Use the picture of my test paper as the "gold standard" for engagement. My gear engagement is much lighter then many I have heard, but is still very secure with no "slap/play".

4. I have provided a picture of the install of the limit switch. Do it like this, and all will be well. Just make sure to KNOW where your Stops need to be placed to avoid over-extending the table. This is especially true if you wish to protect your DRO scales.

- Joined

- Nov 23, 2020

- Messages

- 787

When I wrote this, I had absolutely no idea how gorgeous this would turn out. BRAVO!

My wife and I tend to fall on different sides of this type of spectrum, but she is rubbing off on me. It all falls into what one definition of "nice" is.

On the one hand, we have shiny, new, still has shipping labels on it, painted matchy matchy, and on the other hand, you have worn, honest, overbuilt, useful, heritage, history, etc. I used to fall in the new matchy matchy camp, but my wife is really starting to rub off on me. There are some who would say he is building a better than nice stand.

- Joined

- Jun 2, 2021

- Messages

- 41

Thank you addertooth for the photos and pointing me to the documentation on PM's website. I could not figure out how to attach it to the table. Seems so obvious now that I look at the picture.Here are the pictures I promised. They key things are:

1. The paper instructions which come with the Align Power feed are awful. Go to Precision Matthews website and download the newer (and much better instructions). The paper instructions have you putting the gear on the handle-shaft backwards.

2. Getting the mounting plate LEVEL with the table is vital. Otherwise you will get tilted/pinching gear engagment.

3. Cut a narrow strip of paper to run through the gears to check engagement. It should perfectly fan-fold the paper, without tearing it, but it should leave a clear mark where the teeth squarely engaged with NO Taper. You should do this test with the X-Axis feed moving at a very slow rate. If it is pinching too hard, or tearing the paper, or slowing the motor, then you have the gears meshing TOO Tightly. Use the picture of my test paper as the "gold standard" for engagement. My gear engagement is much lighter then many I have heard, but is still very secure with no "slap/play".

4. I have provided a picture of the install of the limit switch. Do it like this, and all will be well. Just make sure to KNOW where your Stops need to be placed to avoid over-extending the table. This is especially true if you wish to protect your DRO scales.

View attachment 385316View attachment 385317View attachment 385318View attachment 385319

Your effort is most appreciated!

- Joined

- Jun 2, 2021

- Messages

- 41

Thank you guys for all the encouraging and positive comments!

- Joined

- Jul 31, 2020

- Messages

- 765

Not a problem, we are all here to help each other.Thank you addertooth for the photos and pointing me to the documentation on PM's website. I could not figure out how to attach it to the table. Seems so obvious now that I look at the picture.

Your effort is most appreciated!

- Joined

- Jun 2, 2021

- Messages

- 41

I installed the X Power feed and did the paper test. I also added an aluminum channel to the back of the mill so I could move the DRO to a better location for me. The channel will also be useful for doing some cable management.

I tried to do the xy alignment test per David's video. I don't have a machinist square so I thought I'd use my $30 123 blocks. It turns out that those blocks seem to have a 2 thousands error so that did not work out. I'll take it that the alignment is good for now until I get a precision square.

To the best of my abilities and experience the head has a 2.5 thou nod and 2 thou x discrepancy. I'll leave it a that for now.

I'm signing off on this tread.

Talk to you all on some other threads.

I tried to do the xy alignment test per David's video. I don't have a machinist square so I thought I'd use my $30 123 blocks. It turns out that those blocks seem to have a 2 thousands error so that did not work out. I'll take it that the alignment is good for now until I get a precision square.

To the best of my abilities and experience the head has a 2.5 thou nod and 2 thou x discrepancy. I'll leave it a that for now.

I'm signing off on this tread.

Talk to you all on some other threads.