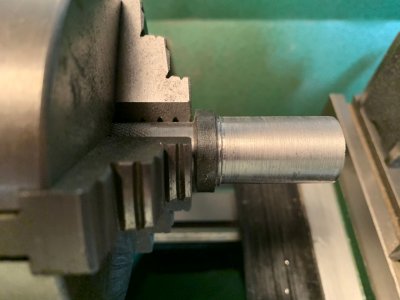

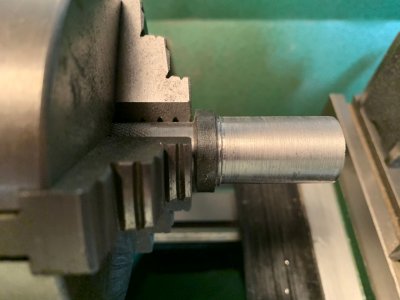

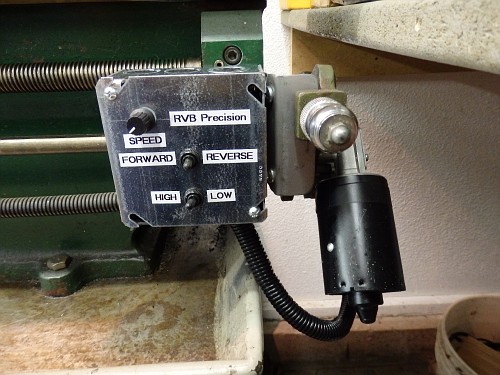

Continuing the saga of my Grizzly G4000 lathe powerfeed problems, I've rigged up a belt drive for the apron handwheel. I replaced the handwheel with a 120T timing belt pulley and attached a small DC worm gear motor with a 15T timing belt pulley and belt. I'm driving the motor with a 12v power supply and a reversible variable speed controller. With this setup, I can drive the apron from 0 to 11 ipm. The picture below is a 10 thou cut of questionable steel (maybe hr) at 660 rpm and a feed rate of 6 ipm using a poorly ground HHS bit.