The Aircraft Engine Historical Society has a web site, "enginehistory.org", and a beautifully-printed newsletter called "Torque Meter" full of good stuff that's not on the site. Back issues are available.

http://www.enginehistory.org/engines.shtml has a book-length article by one of the AEHS guys: No Short Days:

The Struggle to Develop the R-2800 "Double Wasp" Crankshaft, by Kimble D. McCutcheon.

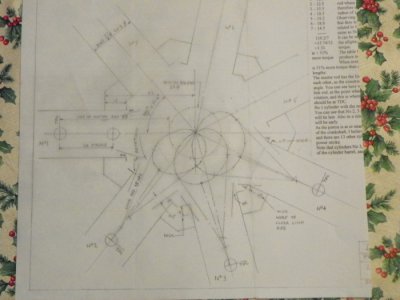

Something that some people don't immediately realize is that only the master rod of a radial engine has a bearing that rotates around the crankshaft. The slave rods have bushings, about the size of the wristpin bushings, and only waggle a few degrees back and forth in relation to the master rod.

A normal piston, rod, and crank layout, like what's probably in your car or lawnmower, doesn't result in a linear motion of the piston in relation to the crankshaft. Instead, if you make a circular plot of the crankpin position in relation to the piston position, the crankpin plot has a slight visible egg shape, fat near bottom dead center. Changing the rod length varies the amount of eggentricity. (this is a common subject of discussion on hot rod forums)

The slave rods are all shorter than the master rod to start with, so their pistons move past BDC and TDC slightly faster than the master piston. The relationship of the lower pin centerline to the crankpin centerline also changes, making the crankpin-to-wristpin distance vary a tiny amount; technically, the slave rods all look like almost-flat toggle joints instead of solid rods. The position of the bottom pin in relation to the crankpin varies as the master rod waggles back and forth in its egg-shaped path.

If you're getting a headache visualizing this, don't worry. The odd motions are quite small, and it wasn't until WWII that anyone worried much about it. Once high supercharging pressures and exotic fuels were used these things had to be revisited, though.

Basically, the motion of the piston near top dead center is a really big part of the spark timing and detonation juggling act. Simplified, The longer you can maintain the burn near TDC, the more complete the combustion and the more power you make. Those tiny variations in piston and crank position mean that when you're really pushing things, your spark event has to be more closely locked to the *piston* position, not the crank position.

That's not a very good explanation, but there are so many interrelating figures it's hard to be both brief and accurate.

The US Government spent a lot of money doing basic research on engine design under the auspices of the National Advisory Committee for Aeronautics. NASA took the archives over and put them online in the 1990s, but they went to a bizarre "improved" interface that I find hard to use. The British government maintains a snapshot of the archive with the old interface at

http://naca.central.cranfield.ac.uk/ This is all the real deal, no "computer modeling". In fact, some of it is more like "hold my beer and watch *this!*" Follow the AERADE link and you can find some of the old British Ministry of Aviation papers online; they mostly deal with aerodynamics, but there's still some good stuff there. I think the British Admiralty was the organization doing most of the engine work, but if their stuff is online I haven't found it yet.