Good day all,

I have a similar problem with my V10 p mentor lathe, 220 volt single phase, the electrics. I am not an electrician AT ALL.

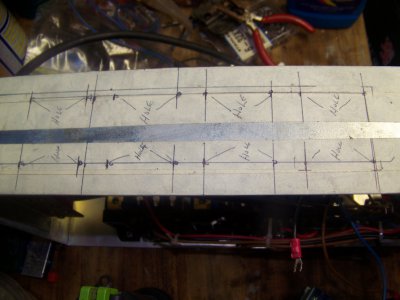

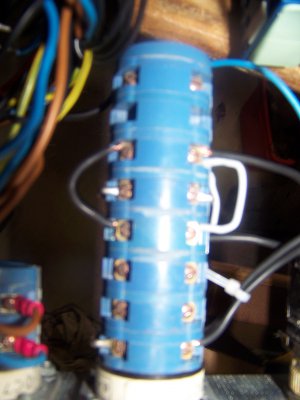

So, having said that, am assembling lathe got all the wiring back as was ??!! thank goodness for colour coding. I have 4 black wires from the rotary switch box to lathe motor loom that sits on the back of lathe above motor [in a box]. I think that they are reverse and forward and 2 speeds can anyone suggest how to identify what goes where or put another way which black wire goes to which black wire. Realize this is bit of an open ended question and lacks specifics but I think there are lot out there who are very knowledgeable in this area. I too had no luck with the Yahoo link cannot even get on.

With thanks Golfpin