- Joined

- Apr 16, 2019

- Messages

- 745

I was wondering how many use round style inserts ? I've used them many years ago but to be honest I can't remember what material or why we we're using them . last night I was roughing an old bar bell weight , interrupted cut , sand ect . I thought it worked pretty good but wanted to know of any others that use them , thanks Al

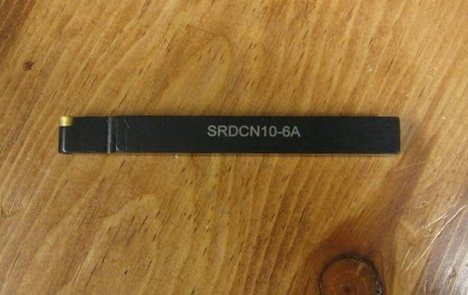

Here's one of what I'm talking about

Here's one of what I'm talking about

HHIP 2037-1210 Style SRDCN 08-10A Turning Tool Holder: Amazon.com: Industrial & Scientific

HHIP 2037-1210 Style SRDCN 08-10A Turning Tool Holder: Amazon.com: Industrial & Scientific

www.amazon.com