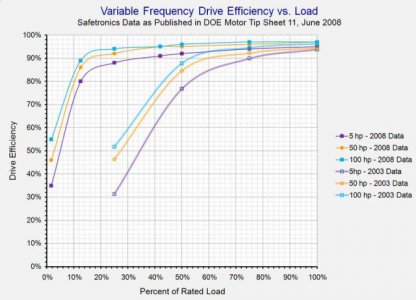

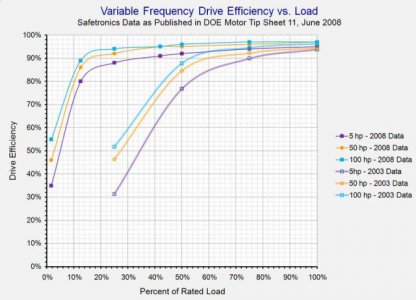

To answer your first question of efficiency, they are about the same at your motor size, probably 90-95%:

http://www.kayind.com/tech_center/FAQ.htm#how efficient

How efficient are phase converters?

Losses are generally less than 15% and usually under 10%. One must remember, however, that only one third of the total energy consumed by the load actually passes through the converter. Therefore, the total loss of the converter system is 15% of 33% or about 5% of all the energy consumed. That translates to 95% overall efficiency.

The answer to your second question "The machines I will have will be a 2hp Series 1 variable speed Bridgeport and a 11" 1 hp logan lathe." is that it depends. At two machines at this small HP size I would say two VFDs are easier and maybe a tad cheaper if you were to purchase an RPC (or by a prebuilt unit and purchase a motor), additional wiring, disconnects, etc. 5 Hp RPC example

http://www.ebay.com/itm/PL-5-Pro-Li...er-Built-In-Starter-Made-in-USA-/290902941590. The break point for going to an RPC is probably 2-3 machines, or powering 3+ Hp 3 phase motors with a VFD. VFDs get pricey beyond 2 Hp models, and the there are very few single phase VFDs in the 3-5Hp range that run off of single phase.

So I would say it is a wash from a price and efficiency standpoint of view if you would see any difference. I have a 2 Hp mill that came with a variable speed drive and I added the VFD to the lathe. I do not have room for an RPC, and it would have been more costly to install and wire. If I had a dedicated shop with more machines, I would power them with an RPC, and then add a 3 phase VFD to machines that I wanted more control on or needed its functions.

Wiring a VFD on a mill is about as basic as one can get, there are many posts on how to do this. Some thought needs to go into the type/brand VFD to purchase (I do not advise the cheap ones on eBay), as to how your going to use it and how you want the controls to work. On the mill, use push momentary buttons for For/Rev, stop and 3 wire control.

The lathe takes a little more TLC if you use the machine's controls, there are numerous postings for a single power relay design that works very well and easy to build (or send a PM and I will send a schematic/info). There are also many forum members that will help you to set-up the VFD parameters or address questions. The benefits of a VFD would be variable speed on the fly, using sensorless vector control on a VFD gives you almost flat torque down to about 20% of the motor base speed (not that one would use the VFD to go that low). It is more to hit the sweet spot without stopping and changing speeds. On the lathe you get controlled acceleration, and electronic braking. The question would be on an older lathe would be how well would it work and are there any motor issues if you have an older motor. Also braking may not be a great idea if one has a threaded chuck. Example of a Logan lathe VFD conversion that went to push button control.

http://www.practicalmachinist.com/v...ine-basic-questions-rookie-270807/index5.html

So I share similar views to professor Dawson, as it all depends. Efficiency and cost wise, it is most likely a wash for the machines you have. If just two machines, then probably VFD gives you added features that you may like. Installation wise, not a big difference, but would probably need to hard wire the RPC in and find space for it. Noise wise, VFD would be quieter (providing you dial up the carrier frequency otherwise they whine like a cat in heat). Also a consideration is to run the 1 Hp lathe VFD off of 120V, which might give you more flexibility as to where to plug it in. Another forum member converted an old 12x24" lathe to a 120V VFD drive, it now runs like a champ.