-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Scrapping at the truck shop

- Thread starter snoopdog

- Start date

- Joined

- Apr 23, 2018

- Messages

- 6,618

Truck stops are great places to pick up material. You just have to be darn careful not to wake the drivers up while you're pulling parts, they get plenty mad about that. When driving the downgrade on the other side of the mountain, they always want their S-cams back.

- Joined

- Dec 27, 2021

- Messages

- 589

Thats why I pull the wrist pins, Safety first!Truck stops are great places to pick up material. You just have to be darn careful not to wake the drivers up while you're pulling parts, they get plenty mad about that. When driving the downgrade on the other side of the mountain, they always want their S-cams back.

- Joined

- Dec 9, 2021

- Messages

- 735

I have several S-camshafts in my pile. I have discovered that they are surface hardened to a depth of over 1/4" and it cost me a band saw blade to find that out. The core is not hard, but is tough. I believe that the intent was to harden the contact surfaces of the cams, the areas that run in the bushings, and the splines for the adjusters. The manufacturer must have decided that it was more practical to just surface harden the whole thing. If you cut the cam off the end of the shaft with an abrasive cut-off saw, you will easily see the depth of the hard temper.

The hard surface can be cut with carbide, but you must use slower speeds. It takes a decent finish if the feed is fast enough. I use brazed point tools in order to be able to regrind the cutting edge, but have used TCMT tooling successfully. It wants to make stringy chips, and takes heavy feeds to break the chips if using a chipbreaker. Expect serious wear on the carbide cutting edge.

I recently made a Drag Link screwdriver socket by cutting a tang on a chunk of this shafting, after turning part of it down enough to fit into the opening of an impact socket. After machining, I inserted the piece into the socket and welded contact area at the mouth of the socket. It worked perfectly. I had to use a carbide end mill because of the hard areas.

The most effective use for these is for drifts to drive out shafts and such. They hold up well to the pounding, and at free, the expense is acceptable.

The hard surface can be cut with carbide, but you must use slower speeds. It takes a decent finish if the feed is fast enough. I use brazed point tools in order to be able to regrind the cutting edge, but have used TCMT tooling successfully. It wants to make stringy chips, and takes heavy feeds to break the chips if using a chipbreaker. Expect serious wear on the carbide cutting edge.

I recently made a Drag Link screwdriver socket by cutting a tang on a chunk of this shafting, after turning part of it down enough to fit into the opening of an impact socket. After machining, I inserted the piece into the socket and welded contact area at the mouth of the socket. It worked perfectly. I had to use a carbide end mill because of the hard areas.

The most effective use for these is for drifts to drive out shafts and such. They hold up well to the pounding, and at free, the expense is acceptable.

- Joined

- Aug 2, 2020

- Messages

- 589

I'm lost. What are these S-cams used for?

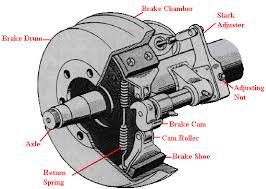

They are the actuators for air brakes.

The S cams expand the brake shoes.

- Joined

- Aug 29, 2016

- Messages

- 838

Air brakes. The shaft between the air bellows and the brake shoes. The "s-cam" is the double eccentric that pushes the shoes.

- Joined

- Mar 31, 2015

- Messages

- 397

- Joined

- Nov 17, 2017

- Messages

- 1,525

Is there a reason trucks don't use disk brakes ?

- Joined

- Dec 27, 2021

- Messages

- 589

They do, it's just relatively new, cost is more upfront. A whole different world, they are not subject to crash ratings either, plastic and aluminum, they fly apart on impact and the driver has no chance.Is there a reason trucks don't use disk brakes ?