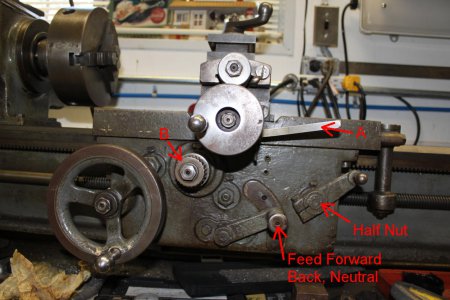

Well, with some PM'ed suggestions from 12bolts, I finally had a chance to check my cousin's lathe. The issues were 1) that I didn't know the proper sequence of engaging the feed, and 2) the cross-feed would lock up mechanically. I ran the following checks by making the settings as shown below and then turning the chuck by hand.

1. Feed Selector: Cross-slide, Drive: Neutral, Clutch: Off

Result: The cross-slide handwheel locked and would not turn, even though the clutch was off. I thought this was odd, because when the carriage was selected with the rest of the settings the same, the handwheel moves freely and moves the carriage.

2. Feed Selector: Cross-slide, Drive: Neutral, Clutch: On

Result: NEITHER the cross-slide nor the carriage handwheel would move at all. Attempting to turn one caused the other to jump, so there appears to be some gear linkage.

3. Feed Selector: Carriage, Drive: Neutral, Clutch: Off

Result: Both handwheels turn freely and move their respective carriages.

The other odd thing is that the feed selector requires virtually no force to move from carriage to cross-feed or back. (Usually; sometimes it's necessary to turn the cross-feed handwheel slightly to get it to engage.) If you literally brush against it, it will switch from one to the other, and that certainly doesn't seem right.

So, it seems to my amateur mind that BOTH the carriage and cross-feed gears are remaining engaged simultaneously, which effectively locks both. Any thoughts, especially on how to fix this?

The other issue was that the tool post was too high. With some disassembly, I realized that the adapter place someone had made for under the post was too thick by about .100 inches, preventing the use of anything but 5/16 inch turning tools. I milled .100 off the thickness (fortunately, my cousin has a milling machine, too) and the tool post will now take 3/8 inch tools and there's enough room to adjust them to the exact correct height for the particular cutting point.

Thanks for reading, and for any comments!

Charlie

P.S. I don't have room for a full-sized lathe, but I *did* just order a Big Dog 7 x 14 mini-lathe. It seems a lot of people get started this way, and I'm really excited about it. I'm already buying accessories; I also ordered a QCTP, tools, etc. from Little Machine Shop!

1. Feed Selector: Cross-slide, Drive: Neutral, Clutch: Off

Result: The cross-slide handwheel locked and would not turn, even though the clutch was off. I thought this was odd, because when the carriage was selected with the rest of the settings the same, the handwheel moves freely and moves the carriage.

2. Feed Selector: Cross-slide, Drive: Neutral, Clutch: On

Result: NEITHER the cross-slide nor the carriage handwheel would move at all. Attempting to turn one caused the other to jump, so there appears to be some gear linkage.

3. Feed Selector: Carriage, Drive: Neutral, Clutch: Off

Result: Both handwheels turn freely and move their respective carriages.

The other odd thing is that the feed selector requires virtually no force to move from carriage to cross-feed or back. (Usually; sometimes it's necessary to turn the cross-feed handwheel slightly to get it to engage.) If you literally brush against it, it will switch from one to the other, and that certainly doesn't seem right.

So, it seems to my amateur mind that BOTH the carriage and cross-feed gears are remaining engaged simultaneously, which effectively locks both. Any thoughts, especially on how to fix this?

The other issue was that the tool post was too high. With some disassembly, I realized that the adapter place someone had made for under the post was too thick by about .100 inches, preventing the use of anything but 5/16 inch turning tools. I milled .100 off the thickness (fortunately, my cousin has a milling machine, too) and the tool post will now take 3/8 inch tools and there's enough room to adjust them to the exact correct height for the particular cutting point.

Thanks for reading, and for any comments!

Charlie

P.S. I don't have room for a full-sized lathe, but I *did* just order a Big Dog 7 x 14 mini-lathe. It seems a lot of people get started this way, and I'm really excited about it. I'm already buying accessories; I also ordered a QCTP, tools, etc. from Little Machine Shop!

Last edited: