- Joined

- Mar 24, 2011

- Messages

- 108

Hi all,

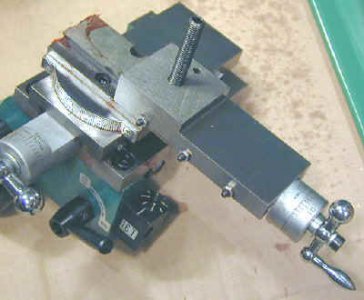

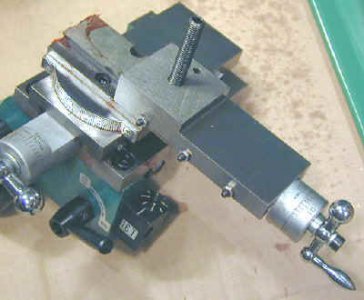

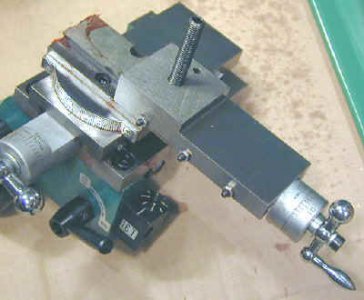

The problem is setting up the compound angle on a mini lathe or, for that matter, any lathe which has the locking bolts located under the compound slide. If I want a given angle I can unwind the compound completely to the right, thus revealing the two bolts and I can then use a protractor to set the desired angle. However, if I want to copy an existing taper, indicating along it's length, I have to loosen the bolts and then wind the compound over the bolts, which means that it is impossible to lock them. In order to lock the bolts the compound must be unwound and it's very difficult to do that without upsetting the angle. I've read that some people claim to copy tapers in a mini lathe but I have no idea how they do it; any suggestions are welcome.

José

The problem is setting up the compound angle on a mini lathe or, for that matter, any lathe which has the locking bolts located under the compound slide. If I want a given angle I can unwind the compound completely to the right, thus revealing the two bolts and I can then use a protractor to set the desired angle. However, if I want to copy an existing taper, indicating along it's length, I have to loosen the bolts and then wind the compound over the bolts, which means that it is impossible to lock them. In order to lock the bolts the compound must be unwound and it's very difficult to do that without upsetting the angle. I've read that some people claim to copy tapers in a mini lathe but I have no idea how they do it; any suggestions are welcome.

José