First, i think I have a problem. I bought a lathe that I have not gotten up and running yet so then I just had to go out and find a knee mill. As if one machine was not enough of a task. Especially for someone who knows nothing about matching other than that I have a lathe and milling machine in my garage. It is in my garage now so there is nothing more I can do.

My new to me (1982 vintage) Shen Wai SW830 8x30 knee mill.

The craigslist post photo

Loaded up on the trailer getting final inspection from the loadmaster.

200 hundred some old miles later I get it unloaded and safely landed in my garage. I had to dissemble the table to get it moved. I am now looking at the table and saddle lubrication system more closely and have some questions. First this is what I have found, the table has ball oilers on the front and the back of the table that correspond with what should be the saddle centered in its travel. The knee ways each have an oil cup for their individual side. Now the saddle. There is no way that is intact or easily reconstructed to oil the lower ways, y travel of the saddle. There is an unidentifiable fitting on each side towards the front (operators position of the saddle. These are not zirk fittings for oil and have a 1/4-20 thread with no o-ring or other type of seal.

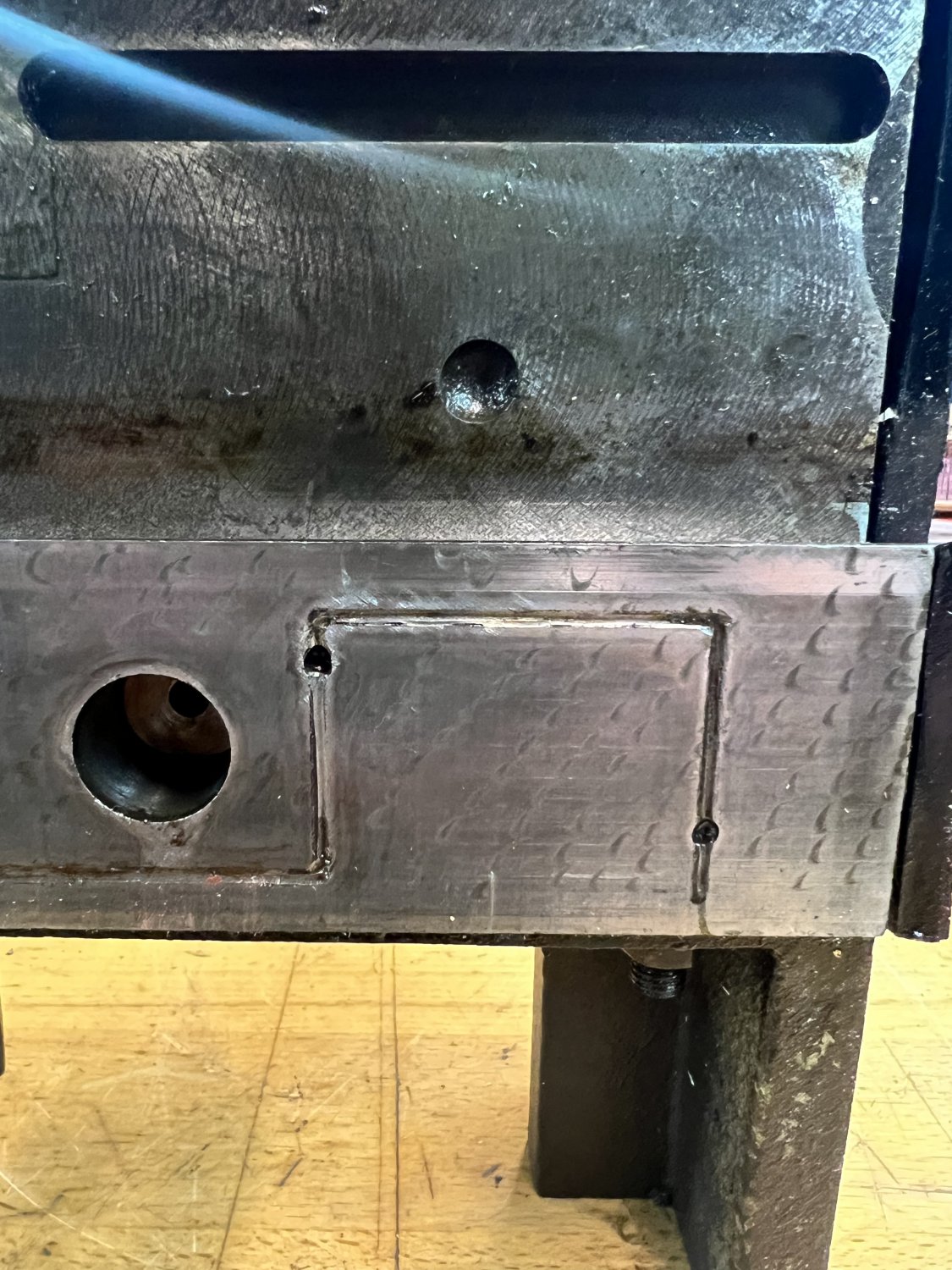

The outer side of the fitting looks similar to a compression style fitting however it is more dished (rounded) and less angular than any face seal I have ever seen. It also makes less sense that it would be some type of compression or tubing fitting being as there is not indication as to what would have connected to it. Also no remnants of mounting for anything else. Also with it being under the table so it would be less convenient to routinely get at for routine lubrication. My machine does not have the one shot or pump style oil system that is available on some of these machines.

I can establish that the oil enters through this port, though the casting into an oil channel cut into the upper way (flat way). Follow that channel a small distance there is another hole that allows the oil to pass through from the upper way to the lower way (v way) so that surface is oiled. Essentially these ports provide most of the lubrication of the for the table.

Overview shot with the front (operator position) on the right

The channel with passage holes

The v way side opening.

Now after all of those photos and jabbering on, let’s get to the question. What was there when the machine was stock? What would be a viable alternative if the original arrangement is no longer viable. Before it gets suggested, I am not in a position to consider adding a one shot or pump oil system. I truly believe that is outside of my current skill set. Also I want to get the machine running so I can learn to use it, not spend the next forever modifying it. It is a hobby machine so it will not see heavy use. As long as I understand the lubrication needs I can keep up on them. Please give me some reasonable, viable, and constructive advice on how make sure things are getting the oil they need.

Thank you to the collective for helping me figure out the conundrum.

My new to me (1982 vintage) Shen Wai SW830 8x30 knee mill.

The craigslist post photo

Loaded up on the trailer getting final inspection from the loadmaster.

200 hundred some old miles later I get it unloaded and safely landed in my garage. I had to dissemble the table to get it moved. I am now looking at the table and saddle lubrication system more closely and have some questions. First this is what I have found, the table has ball oilers on the front and the back of the table that correspond with what should be the saddle centered in its travel. The knee ways each have an oil cup for their individual side. Now the saddle. There is no way that is intact or easily reconstructed to oil the lower ways, y travel of the saddle. There is an unidentifiable fitting on each side towards the front (operators position of the saddle. These are not zirk fittings for oil and have a 1/4-20 thread with no o-ring or other type of seal.

The outer side of the fitting looks similar to a compression style fitting however it is more dished (rounded) and less angular than any face seal I have ever seen. It also makes less sense that it would be some type of compression or tubing fitting being as there is not indication as to what would have connected to it. Also no remnants of mounting for anything else. Also with it being under the table so it would be less convenient to routinely get at for routine lubrication. My machine does not have the one shot or pump style oil system that is available on some of these machines.

I can establish that the oil enters through this port, though the casting into an oil channel cut into the upper way (flat way). Follow that channel a small distance there is another hole that allows the oil to pass through from the upper way to the lower way (v way) so that surface is oiled. Essentially these ports provide most of the lubrication of the for the table.

Overview shot with the front (operator position) on the right

The channel with passage holes

The v way side opening.

Now after all of those photos and jabbering on, let’s get to the question. What was there when the machine was stock? What would be a viable alternative if the original arrangement is no longer viable. Before it gets suggested, I am not in a position to consider adding a one shot or pump oil system. I truly believe that is outside of my current skill set. Also I want to get the machine running so I can learn to use it, not spend the next forever modifying it. It is a hobby machine so it will not see heavy use. As long as I understand the lubrication needs I can keep up on them. Please give me some reasonable, viable, and constructive advice on how make sure things are getting the oil they need.

Thank you to the collective for helping me figure out the conundrum.